I ordered my soft top and tonneau from Robbins. Charley Darley, a BT7 owner from the Capital Area Healey Club recommended Brownings Upholstery in Manassas, VA for soft top and tonneau installation. Although Brownings is located about two hours away, I thought I should try to use a shop with Healey experience, so my son, Scott, and I made the trip to Manassas. I was glad I did as the installation of both components was accomplished with professional results.

Category Archives: BT7 Restoration Assembly Phase

Chapter 90 Week Sixty February 4, 2008

After doing some research on the soft top, I have decided to order a Robbins top and tonneau. I was originally going to use the Sun-Fast cloth material, but have decided to use the material that is closer to the original vinyl. They should arrive this week and then I will decide if I will do the installation myself or get a professional to do the job.

I have discovered that the original drain tap on the left side of the motor leaks and I cannot seem to get it to stop. I ordered a new one, only to discover that it leaks too! I have decided to put a plug in the block in place of the tap.

I have new side curtains and I began the task of fitting them to the car. The RH curtain, although tight in the rear did mount successfully. The LH curtain, on the other hand, doesn’t seem to want to fit properly. I will “play” with it next week and see what I can work out.

Chapter 89 Week Fifty-Nine January 28, 2008

I began some work on the hardtop. The first step was the installation of the aluminum trim and cant rails, followed by the headliner and finally the rubber seals and the windlace. The article prepared by Roger Moment and the photos provided by John Homonek were a big help, but I discovered that advice on hardtop restoration was very limited, so to help others in my spot for the future, I kept a diary of restoration progress. It is available at this web site location: Hardtop

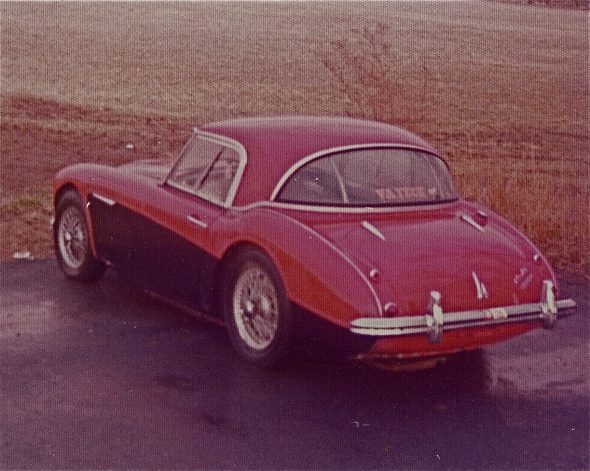

In the photos below, I included an image from 1976 with the hardtop on the car.

Chapter 88 Week Fifty-Eight January 21, 2008

Jeremy Turner came by the house and helped me make final adjustments to the doors. The fit is good, but not quite as nice as I would prefer. The aluminum wings just don’t fit as well with the doors as the original steel wings, but as my wife, Judith, says, “only you and a concourse judge will see that the fit isn’t perfect!”

After finishing up the doors, I put the exhaust clamps on the exhaust system. With the headers and big bore pipes, the exhaust note is a bit louder than the original system, but it sounds great and I can still hear the sound system over the rumble!

The tops and tonneau are the only components that remain. I must say, it feels pretty good to take a look at the Bloody Beast in the driveway. I know it will be even more gratifying to get the Healey out on the road.

Shane and “Little” Shane paid us a visit and, of course, “Little” Shane wanted to inspect the progress on the red car.

Chapter 87 Week Fifty-Seven January 14, 2008

The windscreen was a very tight fit! I suppose that it should be to minimize leaks, but it took some tugging on a drift through one of the lower mounting holes in the stanchion and a lot of pushing to finally get the uppermost capscrew to thread into place. The RH side didn’t require any shimming, but the LH did. You do want to make sure that there is no undue force on the stanchions or you might end up with a broken glass! I added a little 3M caulk strip under the post pad seals and between the windscreen frame seal and the post pad. I decided to run the seal under the post pad, though consulting with the “experts” resulted in at least three ways to do this job: under the pad, between the pad and the post, and cut off flush with the pad. I am using post mounted driving mirrors from Cape International, so they were mounted at this time and tightened through the posts.

After finishing the windscreen, I fixed the original “rainbow” wipers with new rubber to the wiper posts and following the addition of some windscreen washer fluid to the parcel tray mounted fluid reservoirtried out the wipers. All worked fine, including the intermittent wiper rheostatand electric washer pump I has installed previously. The kit from Ed Esslinger also turns on the headlamps when the wipers are activated – a requirement in many states now.

Next was the installation of the bonnet. I first removed the striker pin assembly so that I could have the bonnet lie flat in the surround. Four 1/4” bolts with the heads to the outside are used to fasten the hinges to the bonnet hinge brackets. This process took some adjusting to get things right and at least one assistant is essential! After getting the bonnet lined up I re-secured the striker pin assembly to the bonnet and adjusted it and the bonnet latch support bracket to align all. The anti-rattle spring was then connected to the hood latch remote control rod and the bonnet release mechanism was tried with success.

Chapter 86 Week Fifty-Six January 7, 2008

After a week away from the Healey, I was eager to get back to the final assembly work. Connecting the check strap to each of the doors with the clevis pin was next. I found that making sure the check strap nut was sufficiently tight to hold the door open needed to be done first, then the clevis pin inserted. Both doors stayed open as designed. The RH check strap nut is threaded left handed.

I had pre-drilled the aluminum shut face finishers that were installed following the doors. I discovered that Kilmartin’s are the only ones available that come close to fitting properly. They were sourced from British Car Specialists. The lower sill plate was attached first, followed by the “B” pillar plate. The vertical plate has a piece of vinyl beading glued to the back side to give a finished look to the edge. The aluminum interior door finisher was installed last.

The door striker assembly was then installed and adjusted to line up with the door properly. The assembly consists of the striker, a spacer plate and a drilled back plate. Then the bristleflex door seal from McGregors was installed and the length trimmed to fit properly into the aluminum door seal cap which is screwed into a vinyl covered block of wood.

With the doors finished, it was time for the installation of the windscreen.

Chapter 85 Week Fifty-Five December 31, 2007

Chapter 84 Week Fifty-Four December 24, 2007

Today (Monday) is Christmas Eve and there is much to be done, so only a little Healey work will happen on this day, but I had a good week. I did manage to install the rubber buffers on the front shroud sill bonnet opening. Three on the left side and two in the right plus the long strip to protect the carbs from the weather. My long strip is cut into two pieces to account for the carb access panel. The buffers are held in place by copper-colored split rivets and flat washersthat are pushed through the mounting hole and then bent over.

The next task was to fit the front wings to the superstructure. I began with the RH wing, thinking it would be the more difficult of the two. First, I tapped the wing clip nuts onto the wings. Three shorter nuts and bolts are used for the front of the wing, below the headlights. With the help of my wife, who held the wing in place, I installed the rearmost and forward most bolts.

With those two holding the wing in position, I then began to install the other bolts working from the front to the rear. Each one was hand tightened enough to get them started, but with enough room to install the wing beading. The fourth nut/bolt from the front requires Houdini to install. I finally accomplished it after loosening each of the four bolts securing the heater blower and then disconnecting the large fresh air hose from the blower. With the hose loose I was able to access the bolt for the fourth hole.

To protect the paint while installing the beading, I ran a strip of painter’s masking tape on the shroud and the wing parallel to the beading.

After carefully spreading the beading folding tabs so that they were evenly distributed across the wing, I pressed it in place. Once again, four hands come in handy!

With my wife applying downward pressure on the beading I tightened each bolt/nut until the beading was locked in place and the top of the wing was tight.

Then I tackled the three fasteners below the headlight. These are much easier to access. Again, I loosely attached each of the three and then inserted the two plastic beading pieces between the panels and tightened down.

Next were the three 1/4” x 3/4” long hex head bolts used to secure the bottom edge of the wing. Finally, the 3/8” sheet metal screws were used to fasten the wing flanges to the hinge pillar plate. The heater blower fresh air hose was reinstalled and the blower’s four mounting bolts tightened. A little red touch-up paint on the lower bolts and pillar screw heads and then it was on to the LH wing. NEXT TIME I WOULD WAIT TO FASTEN THE WING AT THE BOTTOM UNITL THE DOOR IS INSTALLED. THERE IS FLEX IN THE WING AND BY MOVING IT UP OR DOWN SLIGHTLY ONE CAN BETTER MATCH UP THE WING CURVATURE WITH THAT OF THE DOOR!

The LH wing was a little easier to install in my case because of the carb access panelI had cut into the shroud! The difficult nuts/bolts on the LH wing were the rearmost two because the wiper motor restricts access to the locating holes and hardware.

It was a good feeling to have all four of the body’s wings in place.

The next task was the installation of the scuttle seals that I had ordered from Bill Bolton. These are reputed to the best available, and the fit does seem to be quite nice. As I was working on the seals and dash pad I had a visit from grandson #2, Shane. As the image shows, he seemed right at home in the Bloody Beast.

Fitting the scuttle seals was not as difficult as I expected. The job was made much easier by following directions: Scuttle Seal Install Rich Chrysler along with those provided by Bill Bolton.

I then installed the dash pad, along with the hot air outlet defroster masks, the mirror, tonneau turnbuckles, and the stud for the tonneau cover.

Once the dash and accompanying hardware was installed I was ready to begin the door installation. I first attached the door check strap assembly to each side. Then I taped all the edges of the wings, sills and doors with painter’s masking tape for protection.

My son John (23 years of age and strong) lifted the doors in place and I ran in the door hinge screws. This job was actually easier and less time intensive than I imagined. Of course, I still need to adjust them for proper fit. I had previously attached all the door interior upholstery, trim and hardware which was much easier than installing it all on the car, but it did make the doors quite heavy.

Next on my list was the installation of the headlight buckets, headlight bulbs, and the chrome lens retaining rim. It wasn’t necessary, but I jacked up the front of the car and temporarily removed the splash shields and the tires to give easier access to the rear of the headlight buckets. I experienced a little difficulty with mounting the trim rim but eventually got it to lock into place. Then I secured the parking/flasher light assemblies to the car with the three small machine screws and nuts, and put the clear lens in place.

I thought I would check out the fit of the grill and immediately noticed that the horns were preventing the grill from sliding into place. I did not have the original horns and I am using later replacements (these are deeper). I ended up switching the LH and RH units and placing them inside their mounting bracket and this seemed to give me the space I needed for the grill. At some point I would love to find the proper horns!

Now it was on to the tow hook/driving light bracket from Cape International. I bolted the brackets into place and fit the Lucas 570 SLR- 5” driving lights, attached the wiring and tested the lights to find them working beautifully. I had previously installed the light relay, an indicator light and the wiring so that the lights only come on when the bright beams are used.

My final work for the week was the installation of the three pieces that comprise the front grille. These were fixed to the car without any issue. The splash panel brackets on either side of the car were fastened to the outside grille mounting brackets.

Chapter 83 Week Fifty-Three December 17, 2007

This week begins my second year of restoration assembly. I have some time off in the next two weeks so I am hopeful that at the end of the Christmas holiday I will have my front body components on the car.

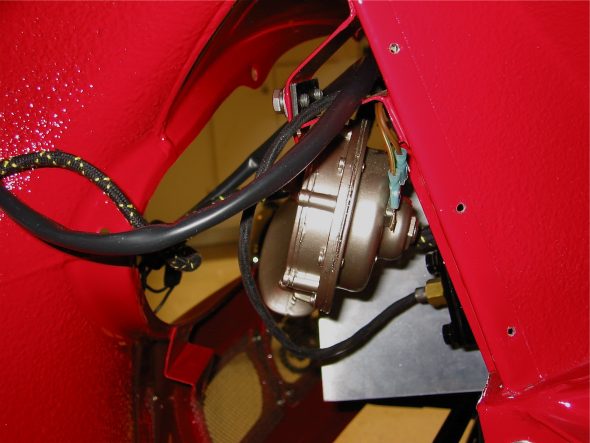

While waiting for the carb repair, I decided to start a little work on the hardtop assembly. Most of my hardtop restoration components came from Bill Bolton. The hardtop fabric he supplies is very close to the original. I has previously refurbished the headliner frame and had it along with the front cushion covered by Gerry Smith at Classic Upholstery. I glued the fabric to the lower hardtop aluminum cant rail.

Fabric was also glued into the corners of the hardtop where the front mounting “J” hooks are located.

Then I glued some carpet padding onto the hardtop to provide cushion for the headliner frame rails.

My repaired front carb returned from Joe Curto yesterday (December 18). Joe replaced the diaphragm. I installed the carbs last night and pleasantly, no leaks! Now I will leave the hardtop work and return to installing the body.

I covered all of the edges of the scuttle that come in contact with the front shroud(bonnet surround) with 3M strip caulk. This will prevent heat, fumes and water from entering the cockpit. To make sure I had adequate build up of the caulk, I used a tip from Jack Brashear. I covered the strip caulk on the scuttle with wax paper, installed the shroud and then pulled it off. Where the strip caulk was not pressed against the the wax paper I added more caulk and repeated the process until I was satisfied that I had enough caulk in place.

Securing the front shroud to the superstructure was the next step. I began by installing 3/16” aluminum pop rivets in the rear of the shroud along the dashboard flange (5) and scuttle edges(2 per side).

I then installed five countersunk flat head screws through the rear flange of the bonnet opening into the edge of the firewall.

Four bolts, washers, and nuts fasten the frame rails to the shroud at the front of the car. The frame rails should fit “inside” the shroud. Three #10 flat head, countersunk machine screws with washers and nuts fasten the front flange of the bonnet opening to the superstructure.

Two #10 flat head, countersunk machine screws with washers and nuts fasten each of the vertical shroud support brackets to the shroud. On the RH passenger side of the car, one of these screws, along with another, is also used to fasten the bonnet prop rod stay bracket.

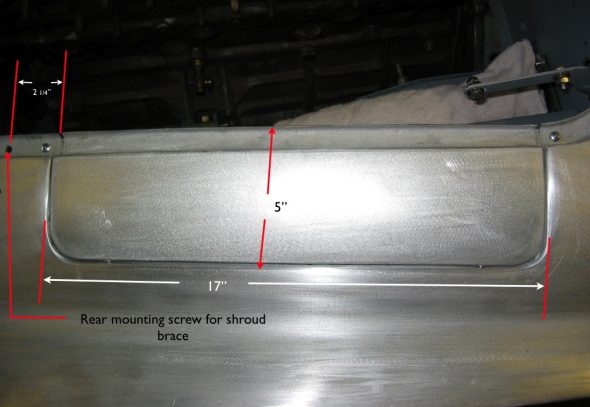

The front shroud was now fastened in place! I then attached the carb access panel and I was in business. The panel measurements are in the image below.

I had a surprise visit from my 9 year old grandson, Tyler. As the photo shows he is getting ready to drive the “Bloody Beast.”

The two windscreen washer jets were installed on the shroud (would have been much easier to do before the shroud was put in place!) and connected with rubber tubing to the reservoir in the parcel shelf. I had previously installed the wiper motor, crosshead and rack, but I now needed to bring the wheelbox assembly up through the front shroud and secure them in place with the rubber washer, chrome bezel and chrome nut. This was not a pleasant job with all the wiring and underdash components in place, but after some struggling the job was accomplished.

Chapter 82 Week Fifty-Two December 10, 2007

I sent my front HD8 carb back to Joe Curto. I suspect a faulty diaphragm causing a leak. When I get it back and on the car then I can finish up the cruise control throttle installation and the front bodywork.

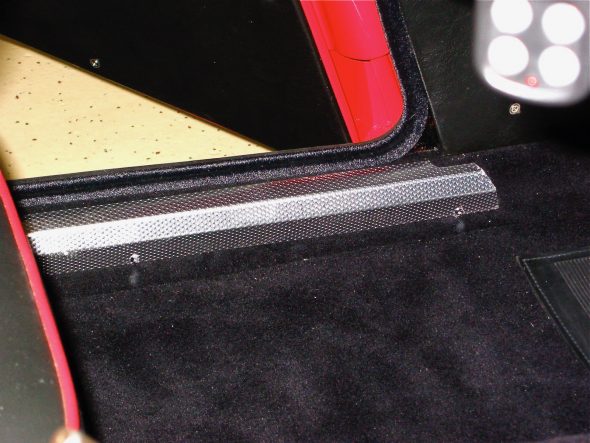

In the meantime I went ahead and installed the rear aluminum cockpit moulding. I used 3M strip caulk to seal each piece to the rear surround lip.

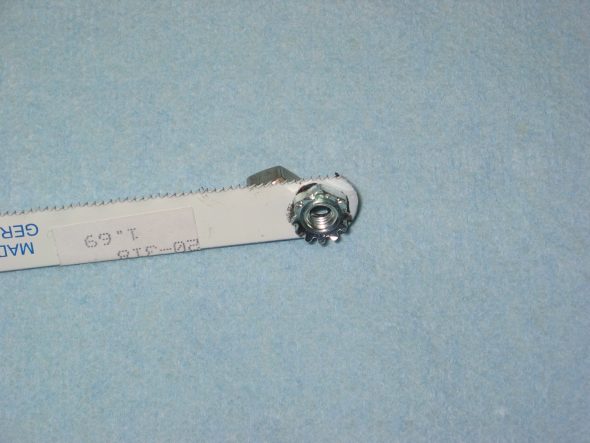

The front-most mounting point for the aluminum moulding was a bit of a problem. After consulting with a number of Healey “authorities,” I concluded that the front mounting point is accomplished with #10-5/8” sheet metal screws on the original car. However, the holes in the shroud had become enlarged over the years and a sheet metal screw would not work. Jack Brashear gave me a tip for installing a machine screw and nut that proved very helpful.

There is VERY LITTLE room to work to install the nut for the front mount. Jack recommended using a Keps nut (has a star washer built in) stuck on a hacksaw blade to maneuver the nut to the fixing hole. I used a little 3M strip caulk to hold the nut on the blade. It worked like a charm and now my moulding trim is mounted tightly to the shroud.