If you scroll down to the October 2018 entry to this Blog you can read about the motivation for what I then called the Ten-Year Renewal Project for my 1960 Austin-Healey BT7. True to my history with this car, everything takes longer than expected! While the care and maintenance of a classic car never ends, now in October 2020 I am going to proclaim that the Renewal Project has come to its conclusion.

The good news is that I have accomplished quite a lot and I am pleased to say that the Bloody Beast is running better than it has ever run while in my ownership, and that covers forty-nine years!

This website has a separate entry for all of the major renewal efforts, so one does not have to read through everything in order to obtain more information about a particular project. However, in no particular order, the following is a summary of all that has been accomplished in the past two years:

- Greased all suspension, steering and handbrake grease zerks.

- Installed a fresh smear of white lithium grease on door locks, bonnet catch and boot lock.

- Checked the ground strap in the boot for tightness.

- Checked tightness of engine mount and shock damper bolts.

- Checked rubber boots on on suspension ball joints.

- Checked king pin wear.

- Replaced fluids in gearbox, engine, hydraulic system, cooling system, rear differential. Replaced the Penrite oil in the steering box and idler with John Deere Corn Head grease to help prevent leaks.

- Checked all dash lights for functionality.

- Checked tightness of prop shaft bolts/nuts at both ends of the shaft.

- Replaced the oil sump gasket with a neoprene gasket from Tom’s Imports and ceramic coated the aluminum sump.

- Removed the PCV system components and installed an oil catch can system.

- Replaced my intake manifold, which had two broken mounting ears due to improper installation, with another good, but used unit, sourced from Michael Salter. Jet-Hot coated the manifold before installation.

- Cleaned and repainted the carburetor heat shield and refreshed the insulation.

- Replaced the chromed “Austin-Healey” front shroud badge with a new component as the paint had chipped away on mine.

- Replaced a leaking RH front Armstrong damper with a newly rebuilt unit from World Wide Auto Imports.

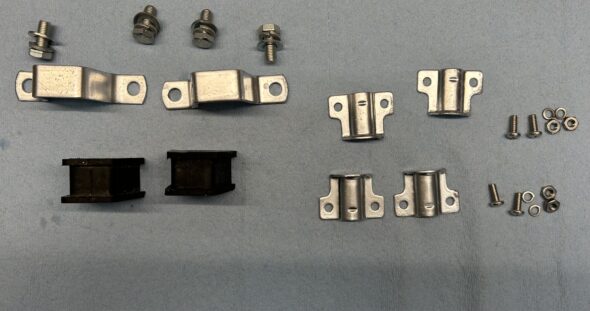

- Replaced ill-fitting rear rally bumper irons with proper irons sourced from AH Spares. The first set had the bumperettes sitting too far from the rear shroud.

- Had the HD8 SU carburetors rebuilt with delrin bushings installed by Thomas Bryant. Replaced both fuel bowl floats with nitrophyl floats. Added fuel bowl “Kouzies” from Joe Curto to insulate fuel bowls from exhaust heat and prevent vapor lock.

- Sealed a persistent oil leak at the rear differential drain plug.

- Adjusted valve clearances to spec. and sealed the cylinder head stud holes to prevent oil leaks.

- Replaced the plastic (nylon?) breather fitting on the rear axle with a brass unit sold by Land Rover.

- Replaced the clutch and brake master cylinders. Inspected the clutch slave cylinder and left it in place. Replace fluid and bled the system.

- Installed a remote clutch slave cylinder bleeder hose from Ol Phartz Parts.

- Replaced the original fuse panel with a seven fuse/fourteen terminal unit sourced from Charlie Hart.

- Fabricated and installed a rear main drip tray below the engine backplate/gearbox to catch oil leaks.

- Replaced the front cylinder block cover gasket to eliminate an oil leak.

- Replaced the alternator with a “new” rebuilt unit.

- Replace the Halogen sealed beam headlights with aftermarket Lucas PL 700 headlights.

- Replaced the original fuel hose delivery system from the hard fuel line to the carbs with a new design and fittings.

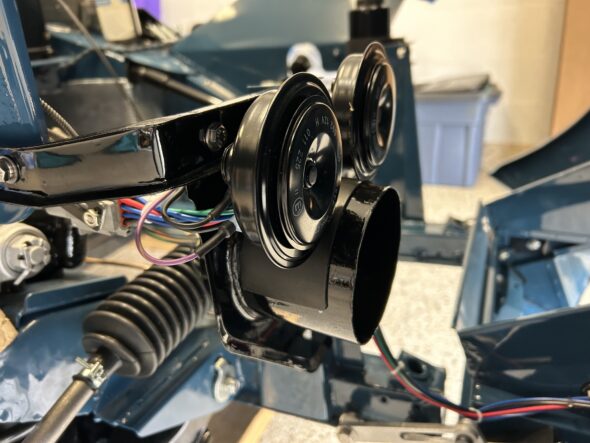

- Added carburetor ram pipes and ITG air filtration socks.

- Added an electric pusher fan in front of the radiator.

- Modified the design of the throttle cable routing to the carburetors from the accelerator pedal.

- New vinyl for the RH door shut face finisher panel side. Will replace the LH side at a later date.

- Installed new ignition wires, rotor, and distributor cap and checked the ignition timing.

- Added a bell housing drain hole for oil leaks from the rear main bearing.

- Replaced the water pump, mounting studs and gasket, fan belt, and upper and lower radiator hoses. Replaced the stainless steel flex fan with an asymmetric yellow plastic (nylon) fan sourced from AH Spares to reduce noise.

- Replaced the 195 degree thermostat (for Virginia) with a 160 degree sleeved thermostat (for Florida) sourced from British Car Specialists.

- Washed, clayed, compounded, polished and waxed the car.

A few things yet to do:

- Replace rubber in wiper arms.

- Replace bristle flex draught excluders (door seal) – will complete when hardtop is off the car.

October 2018

It has been approximately ten years since I wrapped up (if you ever really complete a restoration of a Healey) the restoration of the Bloody Beast. He has weathered the ten years quite well – better than me, that is for sure! I have taken good care of the Beast and completed periodic maintenance as one should. There have been a few things along the way that have required attention, such as the failure of the brake master cylinder that led to the replacement of both masters and the clutch slave cylinder while I was at it. However, for the most part, it has simply been fluid changes, tire replacements and etc.

I am sad to report that I have not driven the Healey as much as I should have during the time since I finished the restoration. About a month after I completed the restoration work I drove the Bloody Beast 8,000 miles in a cross-country trip from Rehoboth Beach, Delaware to California, up the coast to Victoria, BC and then back to Harrisonburg, VA. Between helping my son with his Bugeye, restoring a 1964 Jaguar MK2, and maintaining the 1987 Alfa, a 1969 MB 280SL and the Porsche in addition to the daily drivers there just wasn’t much time to drive! I am ashamed to say that I only put an additional 2,878 miles on the Healey in the ensuing nine-plus years. Driving, however, is the whole point of having a sports car and that is certainly true for an Austin Healey roadster. My son has now taken the Bugeye to his home. I have sold the Jaguar and the Mercedes. I now intend to spend more time driving the Bloody Beast!

After almost ten years I thought it might be healthy to go over the car carefully and examine the condition of components, check tolerances, and replace items that typically wear – even though they might be in operable condition at the moment. I will be making myself a list of items, that will probably not be in any particular order, and I will undertake some of the work as the list is added too over time. I will gradually need to accumulate parts for the work to be done.

For those who read this post, I hope you will contribute through your comments and make suggestions about anything, but particularly about items that should be added to my ten year renewal list. To be clear, an item on the list, an oil change for example, doesn’t mean that it is only to be done every ten years. I will make entries on this post chronologically as items are accomplished. I will keep a ten year renewal checklist as a separate post and add to it as I think about items to address. I will organize this list based on the categories of the Workshop Manual.

So, lets start this project! The most recent actions are listed first: Ten Year Renewal Blog