I sent my front HD8 carb back to Joe Curto. I suspect a faulty diaphragm causing a leak. When I get it back and on the car then I can finish up the cruise control throttle installation and the front bodywork.

In the meantime I went ahead and installed the rear aluminum cockpit moulding. I used 3M strip caulk to seal each piece to the rear surround lip.

The front-most mounting point for the aluminum moulding was a bit of a problem. After consulting with a number of Healey “authorities,” I concluded that the front mounting point is accomplished with #10-5/8” sheet metal screws on the original car. However, the holes in the shroud had become enlarged over the years and a sheet metal screw would not work. Jack Brashear gave me a tip for installing a machine screw and nut that proved very helpful.

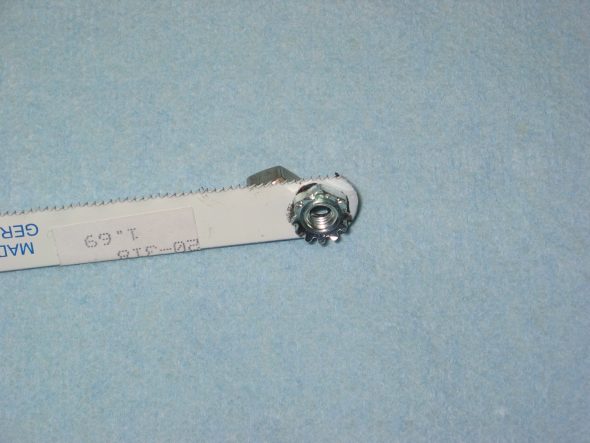

There is VERY LITTLE room to work to install the nut for the front mount. Jack recommended using a Keps nut (has a star washer built in) stuck on a hacksaw blade to maneuver the nut to the fixing hole. I used a little 3M strip caulk to hold the nut on the blade. It worked like a charm and now my moulding trim is mounted tightly to the shroud.