Daily Archives: March 15, 2020

Chapter 50 Restoration Assembly, Week Twenty 4/30/2007

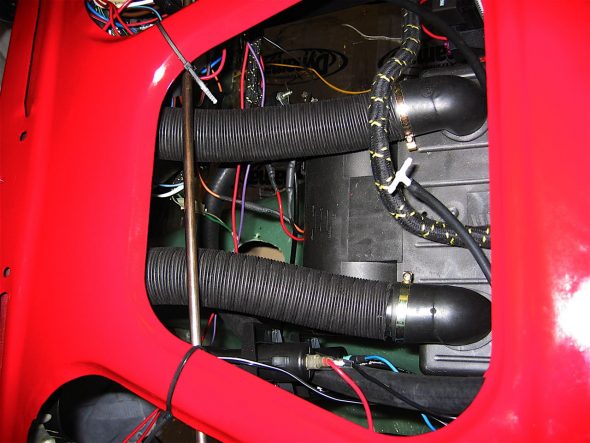

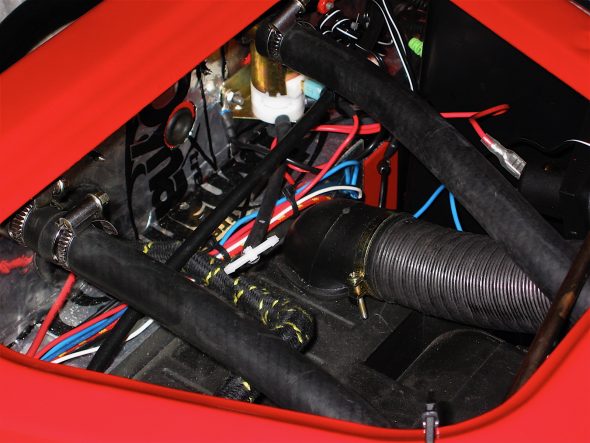

Rather than using the original Smiths heater, I am taking advantage of more modern technology and substituting a two speed heater available from Cape International. The heater unit integrates the hot water radiator as well as the fan blower. I had installed the heater unit previously and the time had come to put the demister hoses in place. These install basically as on the original.

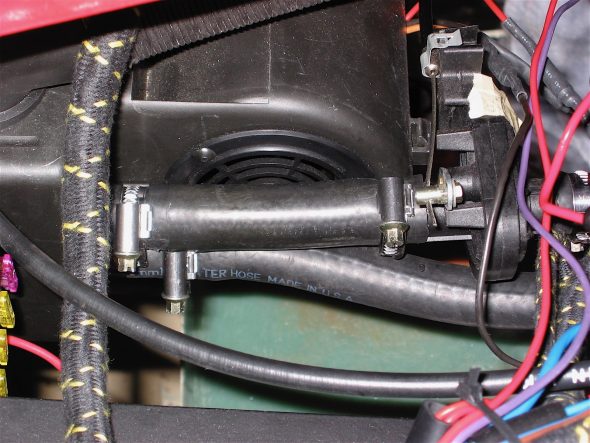

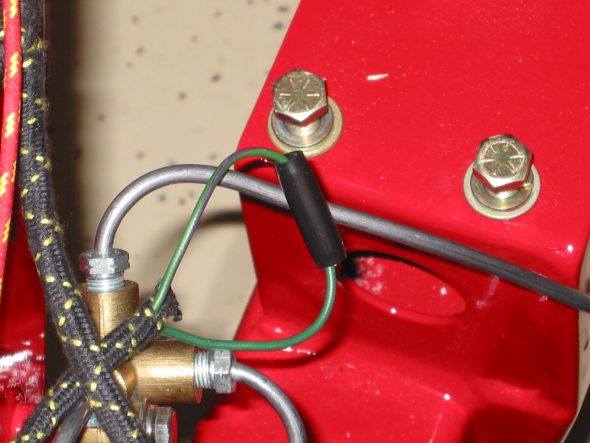

The next task was to install the hot water heater hoses. The kit is supplied with brass step down joints as the interior diameter of the hose at the heater and at the control valve is larger than the hose that connects to the heater control tap on the motor and the water return pipe.

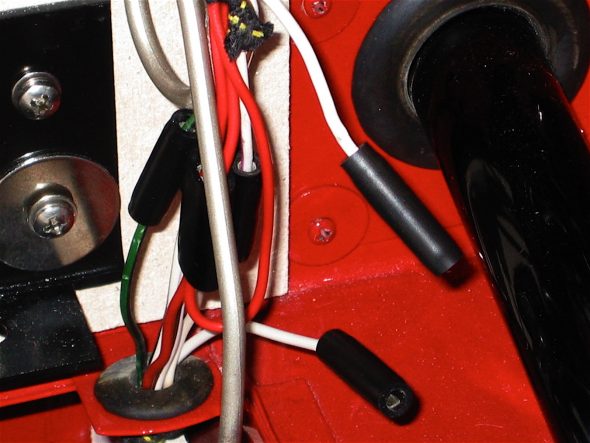

The wiring for the ground connection and the power to the two fan speeds is sadly visually obvious from the interior seating. To obscure the wiring a bit, I ran all three wires through a length of heat shrink tubing.

Then the Cape heater water control valve was connected to the original heater control panel by a short length of bicycle derailler cable. Since I am using the overdrive switch to control the two speed heater fan, the switch on the heater control panel is available to control the original Smiths blower to bring fresh air into the passenger seating area. Whether the new heater works any better than the Smiths unit, I don’t know. We will see come next winter!

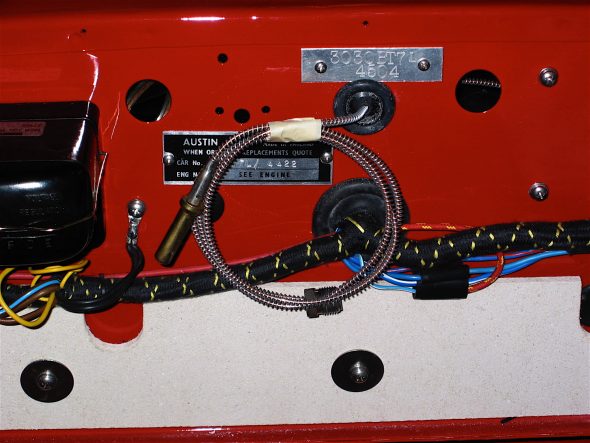

It was now time to move to the boot to install the Armacord and fuel tank. I ordered my Armacord kit from Heritage Upholstery. I began with the vertical piece through which the battery cable runs and then moved to the right and left pieces that fit the rear inner quarter panels. I brushed on Weldwood contact cement for the adhesive on the body components and used 3M spray adhesive for the back side of the Armacord.

The left rear wheel arch was difficult to cover without some minor buckling. I was not entirely satisfied, but in this case, my less than perfect fitting will be covered by the spare tire.

I then installed the vertical rear Armacord panel. In addition to gluing this piece in place I installed three pop rivets as original. I also installed three #8 stainless self-tapping screws and trim cups through the Armacord and into the rear bulkhead wall.

The two spare tire wood blocks and tie down hardware were then installed. I am using Michelin ZX 175 tires that required repositioning of the left quarter panel block, raising it about 1/2.” I made a new longer and thinner wooden block for the rear bulkhead so that I could continue to use the original mounting holes.

Chapter 49 Restoration Assembly, Week Nineteen 4/23/2007

Four university students (young, strong backs) arrived and helped me install the assembled rear axle in about five minutes. The install was accomplished with just one minor scratch!

I am pleased that I assembled everything on the bench first. I don’t know if it would have worked with the panhard rod in place, but since I am using the Jule frame I don’t have a panhard rod.

I put the rubber buffers in place on the axle and installed the U-bolts supplied by Martin Jansen to fit the springs he had made for me. I did need to open the hole in the spring plate to accommodate the larger pin in the springs.

The lower brackets for the Udo Putzke Bilstein shocks were attached to the spring plates. The next task was to bolt on the upper brackets for the Bilstein tube shocks to the original shock mounting brackets. The Bilstein shocks were then installed on the brackets.

The handbrake cable was then put into place and adjusted for the the proper tension on the emergency brake calipers.

The rear flexible stainless steel flex pipe for the brakes was then mounted to the car.

Final fuel hose connections were then made from the two pumps to the steel line running to the carbs.

The ground strap was connected to the frame. The other end will later be fixed to one of the bell housing bolts.

Chapter 48 Restoration Assembly, Week Eighteen 4/16/2007

I decided to completely assemble the rear axle for installation into the car. I will recruit four weightlifters to help with placement!

Jeremy Turner worked his magic and made the axle assembly look brand new in its glossy black. I installed the bearing carriers with new bearings, “O” rings and paper gaskets. I lightly coated the gasket between the bearing carrier and the axle half shafts with hylomar sealer.

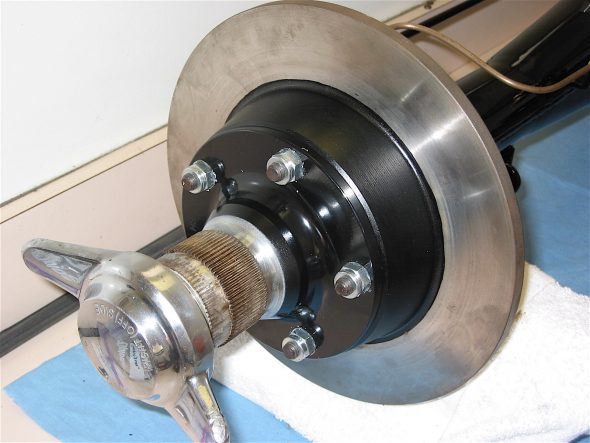

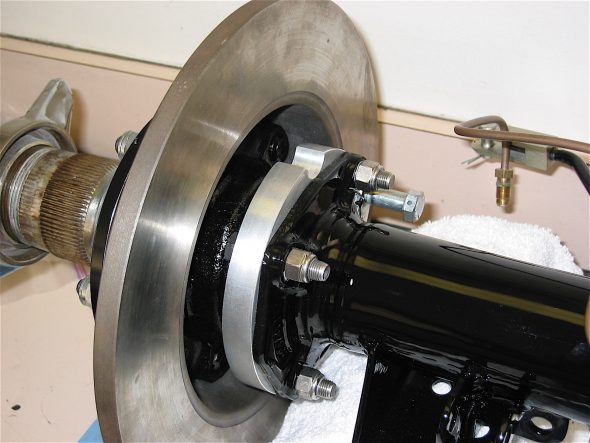

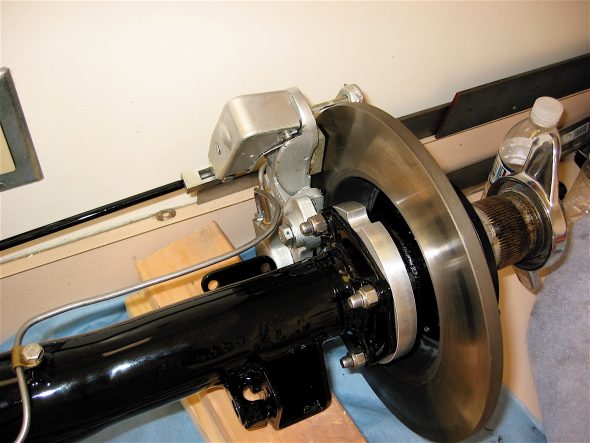

I am using Cape International’s rear disc brake conversion kit to replace the original rear drums. Cape Int Disc Brake Conversion 1 The kit is nicely done including aluminum caliper mounting brackets, drilled mounting bolts (drilled for safety wire), a template for modification of the axle flange, disc rotors, locking conical hub nuts, jaguar calipers including ancillary handbrake calipers and brake pads, and a threaded rod with end fittings to connect the LH and RH handbrake calipers. I did have to “rework” the short connecting rod to obtain proper alignment, but otherwise, everything was a bolt-on job.

Chapter 47 Restoration Assembly, Week Seventeen 4/9/2007

There wasn’t much time available for Healey work again this weekend. I did install some more Dynamat product over the interior floorboard and the propshaft tunnel. I was then able to glue the black interior vinyl around the handbrake bracket on the tunnel.

I then installed my rechromed handbrake lever and its mechanism including attaching the cable to the lever and to the bottom of the floor pan to keep it from fouling the propshaft.

Using contact cement, I glued the foam rubber seal to the bottom of the boot in preparation for the fuel tank fitment.

Chapter 46 Restoration Assembly, Week Sixteen 4/2/2007

Ah, yes! Finally back to some Healey work. I had planned to use an amplifier mounted under the parcel shelf, bookcase speakers behind the dash fascia, and a small subwoofer in the boot for my sound system. No radio needed, just planned to plug my iPod into the amp.

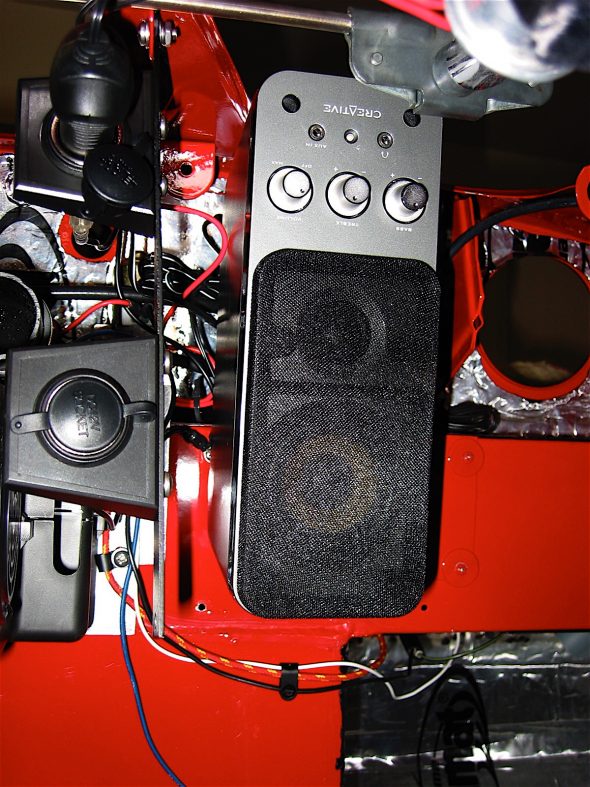

Roger( AUSMHLY) on the British Car Forum recommended using some amplified two-way computer speakers made by Creative Speakers.pdf. Doing so would mean no additional amplifier and no subwoofer and they only cost $99 for the pair. I decided to try them.

For a power source I used a Power Adapter.pdf from Radio Shack with a “M” size adaptaplug. I plugged it into a accessory Power Outlet.pdf also from Radio Shack mounted on the vertical support brace for the parcel shelf. I mounted it high on the brace and it is not visible from the interior.

To support the speakers I made a couple of steel “L” brackets and screwed them into the speaker casing (carefully) and then mounted them to the fresh air plenum, to the left of the steering column and over the passenger parcel shelf. The photos show the idea. Sorry for the messy wiring. I will clean that up before I finish the electrical work!

I am eager to try this new sound system on the road because it sounds terrific in the garage! Thanks to Roger for a great idea.

Chapter 45 Restoration Assembly, Weeks 12-15 3/5 to 4/2, 2007

Chapter 44 Restoration Assembly, Week Eleven 2/26/2007

Time to install my Moto-Lita steering wheel and my rebuilt control head (trafficator) Trafficator(low res).pdf . This pdf will take a little while to download – lots of images! The installation was fairly easy and straight forward. I inserted a length of thin wire up the tube and wrapped it around the first bullet connector on the wiring harness from the control head. I was then able to pull the wires down through the tube. I centered the wheel and tightened up the olive and nut at the bottom of the tube. Then tightened the three set screws on the steering wheel hub.

After installing all of the electrical modifications I have made, I wanted to test things to make sure all connections were as they should be before moving on to the next task. So, even though I will disconnect them for final assembly at a later date, I wired the driving lights, headlamps, turn signals/brake lights as well as the license plate lamp.

The battery was then installed and (big breath) power applied to the system. One-by-one I checked the function of all systems. The right rear tail light turn signal did not function, the accessory lights did not turn on when the “clicker – remote control” was activated, the horns did not sound and my driving lights still needed some work. These items will be sorted out, one at a time, until everything is working properly. A little work remains, but I didn’t burn down the house or melt the car – a significant accomplishment!

I rechecked my wiring for the driving lights, made one change, and they are now functioning properly including the indicator light I installed on the new switch panel.

I made sure all of my ground connections were clean and tight and replaced the original flasher canister with a new one and now the flashers are working properly. The terminal connections are different than the original. Terminal X is equivalent to B (battery feed from fuse box — green wire),

Terminal L (Load, i.e., the feed to the bulbs — green/brown wire) and terminal P (Pulse, to the dash lights — light green/purple wire). Just as an aside, I did pop open the new flasher relay box to examine it for potential problems, only to discover the circuit board of a new solid sate unit rather than one with the original design.

Following a consult with Michael Salter, I concluded that the reason my horn was not working was that the steering box was not grounded due to the paint on the box and the frame. Once some paint was scraped away from both I obtained a solid ground and the horn “honked” properly! I rechecked my wiring for the interior accessory lighting and they now function properly also.

Chapter 43 Restoration Assembly, Week Ten 2/19/2007

All of my electrical modifications are taking longer to sort out than I expected, but I am no electrician so I am extra careful and take my time with these matters. Next up was the inclusion of an Accessory Power Supply (Cigar Lighter). I want the car to be equipped to handle the electrical needs of a number of electronic accessories such as an iPhone, navigation system, and etc.

I ran a light blue wire from the cigar lighter to the switched side of the ignition. An in-line fuse was incorporated into the power connection. The other terminal on the cigar lighter was connected to a black ground wire fastened to the firewall.

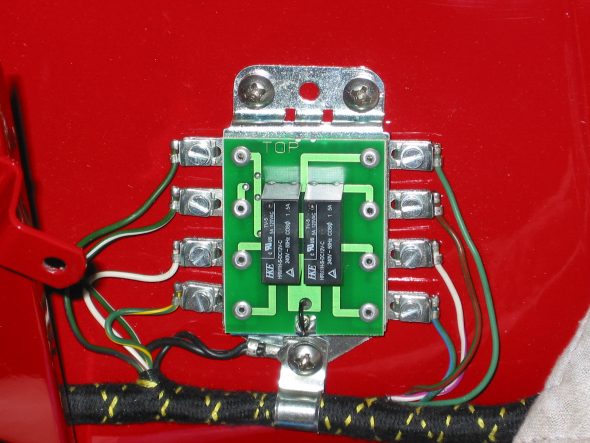

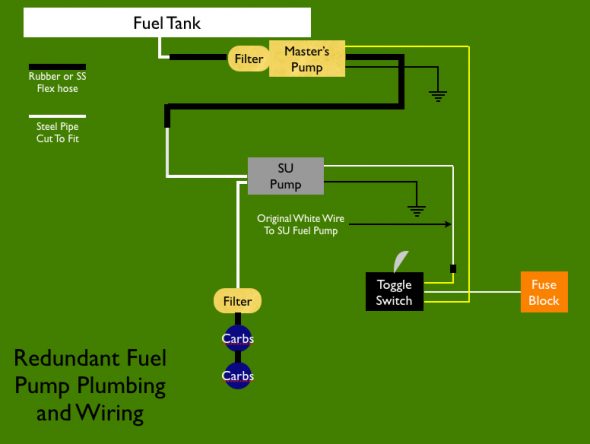

While I always planned to use an SU fuel pump, I decided to upgrade to a solid-state unit with negative ground. Additionally, I thought that now was time to build some redundancy into the fuel delivery system so I included a secondary Master fuel pump (get specs at web site) into the flow in case of a problem with the SU. Both pumps are of the flow-through variety.

I installed the Master fuel pump on the vertical wall of the boot, taking advantage of one of the mounting bolts for the fuel tank mounting straps in the boot. I inserted a piece of rubber between the pump mounting bracket and the boot wall to help with vibration damping. I then cut the steel pipe as it exits the fuel tank and installed a new rubber fuel line from the back of the fuel tank to a fuel filter that feeds the Master pump. A rubber fuel line was then run from the outlet of the Master pump to the shortened steel fuel line entering the SU pump. Exit from the SU pump is as original. I mounted the pump on the right side of the car to avoid the heat of the exhaust pipes on the left side.

As mentioned previously, I installed a toggle switch on a fabricated panel just below the wiper motor to control the selection of the pumps. With a flick of the switch I can move from one pump to the other. I connected the center terminal, terminal #2, of the toggle switch to the white wire from the fuse block that originally connected through a rubber bullet connector coupler to the white wire in the harness running under the car to the fuel pump.

Terminal #1 on the toggle switch was connected to the original white wire running under the car to the SU pump. Terminal #3 was connected with a new yellow wire to the + terminal on the Master fuel pump. Black wires on each pump were connected to ground locations to the superstructure of the car.

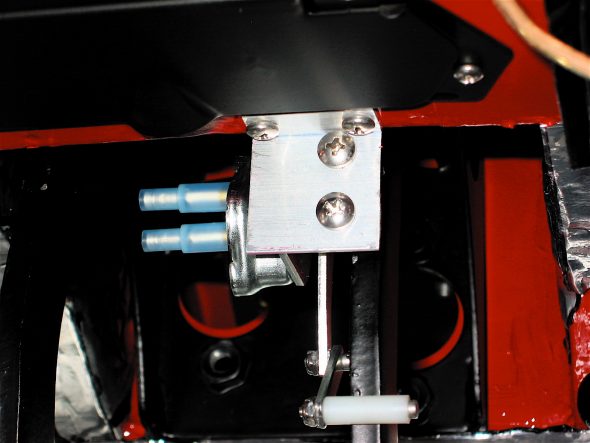

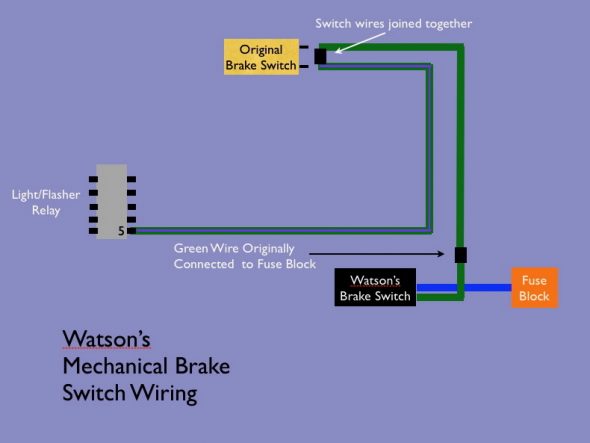

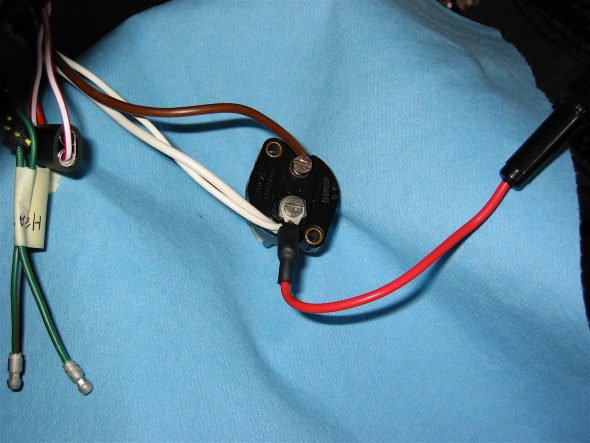

The hydraulic brake switch available today to replace the original Lucas unit has, according to many Healey owners, failed after only short periods of time. An alternative is to use a mechanical brake switch located by/on the brake pedal. I chose to use a switch available from Watson’s Street Works and followed installation guidance from Steve Gerow and Dave Carpenter.

I first made a small mounting bracket, mounted the switch to the bracket and then mounted the assembly to the bottom of the sheet metal below the fresh air heater box. The contact arm on the switch is easily adjusted to register against the brake pedal per the instructions provided from Watson’s.

I did not want to route wiring for the switch parallel to the harness through the engine bay to the original hydraulic switch, so I isolated the green wire at the fuse panel that provides power to the switch, disconnected it and connected one terminal on the new brake switch to it. I added bullet connectors to the ends of the green and the green/purple wires at the hydraulic switch and joined them together with a rubber coupler. Finally, I ran a new wire from the other terminal on the Watson’s switch to the fuse block as a power source.

With the wiring behind me, I decided to center the steering wheel shaft in the dash fascia and proceeded to tighten those components that are affected by the wheel position: The steering bracket, the two plates with rubber seals around the steering shaft – one inside the interior and one in the engine compartment, and the three fixing bolts on the steering box.

Chapter 42 Restoration Assembly, Week Nine 2/12/2007

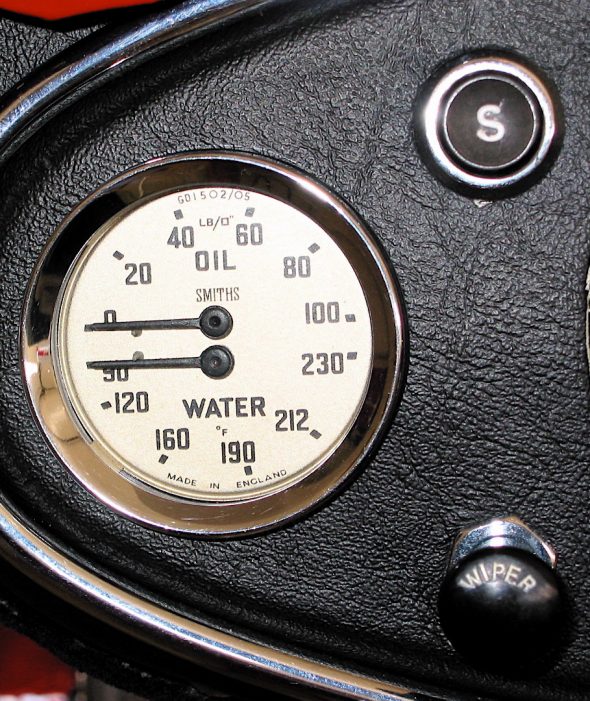

I began the wiring of the dash instruments, gauges and switches with the water temperature and oil pressure gauge and moved across the face of the dash from left to right with the exception of the speedometer and tachometer which were left until the end. The openings for these two instruments provide access to the back of the dash.

The gauges/instruments were all rebuilt by MOMA and they did a beautiful job.

Before connecting the oil pressure gauge I inserted a new small leather washer that prevents oil from dripping on the driver’s leg! The washer was available from British Car Specialists.

The following is a summary of the wiring connections I made. Although this worked successfully for me, in no way do I suggest that this listing is a substitute for the diagram in the workshop manual. Anyone wiring their own vehicle should consult the manual for proper direction.

Ignition Switch #22 – Brown/Blue wire to right terminal #1; two white wires to the left terminal #2, twist together.

Tachometer – Yellow and White wires to the tach light bulb; black double wire is the ground for the tach.

Fuel Gauge #32 – Two solid green wires to terminal B; one green/black wire to the T terminal; red/white wire to fuel gauge light bulb.

Light Switch #25 – Blue wire to the S2 terminal; two brown/blue wires to the A terminal twisted together. The wiring to this switch was modified to permit the intermittent wiper control module to also turn on the lights when the wipers are activated. This simply required running a blue wire from the module’s relay to the S2 terminal, and running an additional brown/blue wire from the relay to the A terminal on the light switch. Details on this assembly were provided in the week eight blog installment. I also installed an in-line fuse into the red wire leaving the S1 terminal.

Overdrive Switch #39 – See the details in Heater switch below.

Flasher Warning Light #24 – Light green wire bulb

Speedometer #30 – Light blue/white wire light bulb. Two black wires to ground.

Wiper Switch #27 – These connections are modified to accommodate the intermittent wiper control. The white/yellow wire from the wiper control module is connected to terminal #1 on the dash wiper switch (replacing the black/green wire.)

The black wire from the wiper control module is twisted together with the black wire from the wiring harness and connected to terminal E of the wiper switch.

Starter Button #23 – two white wires twisted together to terminal #1; one white/red wire to terminal #2.

Water/Oil Pressure Gauge – red/white wire light bulb

Panel Lamp Switch #34 – I decide to leave the panel lights on all the time which made the panel light switch available to be used to control the auxiliary driving lights.

The single red and double red/white wires originally screwed to the panel light switch were connected together with bullet connectors and a double rubber connector sleeve.

The ground is used in the auxiliary light wiring system to complete or break the circuit. A black wire from the relay is connected to the panel lamp switch and then a black wire is connected from the other terminal on the panel lamp switch to a ground connection on the firewall.

Heater – I am using a “modern” heater to replace the Smith’s unit under the dash. The new unit was available from Cape International. It uses a two speed fan that is internal to the unit. The Overdrive Switch is not used for that purpose on my car since I am using a Smitty conversion Toyota 5-speed gearbox. Therefore, I replaced the switch with a DPDT switch and used it for the heater control. The red wire (high speed) was fastened to one terminal of the switch, the orange wire (low speed) was fastened to the terminal on the other side of the switch, and the yellow wire from the supplementary fuse panel was connected to the central terminal on the switch to provide power to the unit. So I ended up with a convenient heater control without having a change in appearance of the dash or locate a switch in some hidden place.

Smith’s Heater Blower Fan – Since the new heater contained its own fan, the Smith’s Blower was available to be used as a blower for fresh air to the passenger (right side) compartment. I will discuss it further when I come to the installation of the new fresh air supply components.

Heater Switch #26 – The green/brown wire to the black bullet wire connector on the switch. The green wire to the black bullet wire connector on the switch.

Windscreen Washer Pump – I read a technical article by Stu Brennan, an owner of a Sunbeam Tiger, who had converted his hand activated pump windscreen washer to an electric washer. I like the idea because he put the electric switch in the aluminum canister thereby eliminating the need to install an additional switch somewhere. Since the washer in the Tiger is the same as the one in the Healey, I decided to give it a try. These links provide Stu’s instructions for his car and my interpretation for the Healey. The fused red wire is connected to the purple switched wire from the supplementary fuse panel. The other red wire from the washer canister connects to the washer pump. Elect Washer Pump Comp and Rose Elect. Washer Pump Comp.

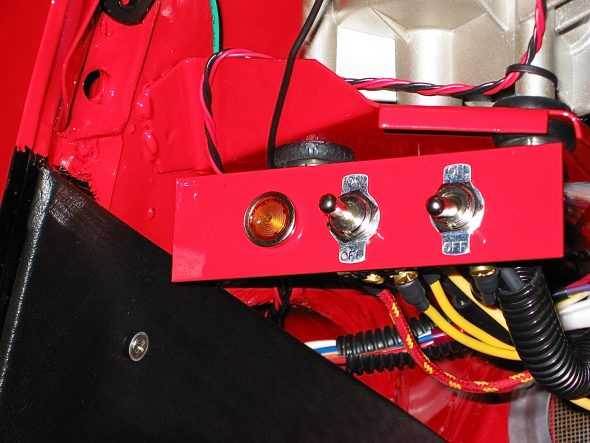

Toggle Switch Panel – Try as I did, I could not find enough places to provide switch controls in original mountings (overdrive switch and panel lamp switch as examples) for every accessory or modification that I wanted to add, so I made a small panel out of aluminum stock (1 1/4″ L stock) to house two toggle switches and an indicator light for the auxiliary lights.

I mounted the switch panel to the front two screw posts for the wiper motor. I will still successful in mounting the switches without drilling any new holes in the car! The bracket is painted red to make it less obvious, although it is concealed pretty well anyway.

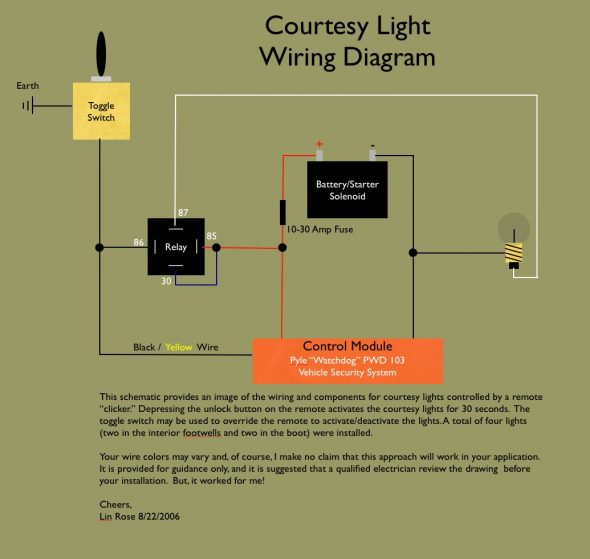

One of the toggle switches will be used to override the remote control for the interior/boot courtesy lamps. Using the remote “clicker” the lights stay illuminated for only 40 seconds, but the toggle switch can be flipped “on” to leave the interior lights on until flipped “off.” The second toggle switch will be used to activate the redundant fuel pump when needed. In the “up” position the original-type SU pump is activated. In the “low” position the second Carter pump is activated. In the center position neither pump is activated – a good ani-theft device!

Finally, an alert lamp is include in the panel that notifies the driver that the auxiliary driving lights are on.

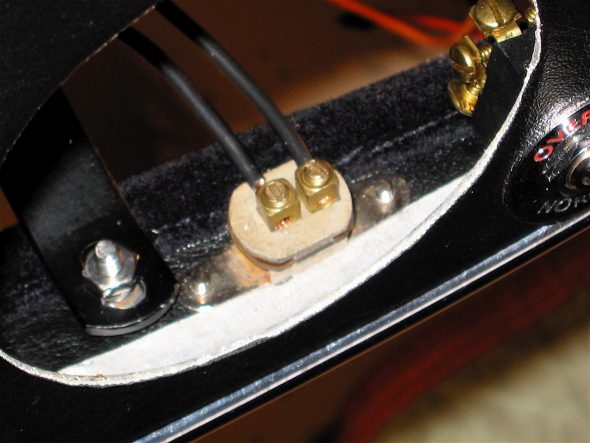

Interior Courtesy Lamps – Purists will get another chuckle out of my addition of remote control courtesy lamps in the footwells of the interior and in the boot. Again, I did not want to drill any holes in the car for door jam switches so I thought, “why not use electronic remotes used in modern cars to unlock doors, open boots, and set off alarms to activate the lamps?”

The remote control system I acquired from Pyle was about $40.00. It included two remote “clickers,” the control module, and the wiring. I grossly underutilized all that the Pyle system makes possible, but I was after simplicity. I just cut off all the extra wires, but I can imagine a few other very practical uses. The button on the remote typically used to unlock the car (obviously not needed on a BT7 roadster) is now pushed to activate the interior/boot lamps. As I approach the car at night, I can click the remote and my interior lamps will come on for 40 seconds and they extinguish on their own with not other action required. As noted above, a toggle with is also wired-in to control the lamps.

The lamps are some fairly primitive incandescent fixture purchased from Victoria British, part #15-642, but sine they are not easily seen I was not too concerned about their physical appearance. I made some simple brackets and mounted them in the footwells on each side of the car, along with the control module and its relay. Again, placement of the lights was determined by available mounting points so additional holes in the car were not required. A boot light adapted from a period license plate illumination lamp was also installed.