The front hub assemblies were the next parts to tackle. I had previously assembled new hubs to new drilled rotors. I fastened the rotor disk to the hub extension with 5 nylock nuts. Placed bearing races in the freezer so they would be easier to install in the front hub extensions. Then inserted inside bearing race with proper driver with the careful application of a hammer!, being careful to keep the race/driver straight. Turned the hub over and did the same procedure with the outside bearing race.

Bearing Race Install

Front Hub Bearings – Norman Nock and Doug Reid Doug Reid’s Front Wheel Bearings.pdf have produced some pieces that were very helpful for this process. I followed directions from Bruce at Healey Surgeons and put 90 weight oil on the inner bearing and offered it up to the spindle. The oil provided protection from damage due to the bearing running dry but at the same time, not give a false reading when trying to shim the bearings.

I then placed the spacer (cone) on the spindle followed by the hub extension. I then put an oil filled outer bearing on the axle followed by the tab washer and castle nut. The seal and shims were NOT added at this stage. The nut was tightened down to seat everything and then the works were disassembled. It can be difficult to get the outer bearing and the tab washer off – I used a magnet that worked quite well.

I then put the inner bearings, the spacer and selected shims on the axle. Starting with the thickest one .030, then .010, .050, .030, ( one of each ). I then put the hub extension on the axle followed by the outer bearing, tab washer and nut. I tightened to 40 lbs of torque and determined if one of the castle nut slots lined up with the hole in the axle for the split pin. I took care that the shims were all the way up on the shoulder of the spindle axle so that they did not get mangled when the nut was tightened. The final proper adjustment is correct when you can tighten on the nut and the wheel does not show any reduction in ease of turning with no play.

Bruce indicated that if the rotor drags when you tighten the castle nut, then you need to add shims. If it is to loose, you need to remove the shims. When it is correct, re-tighten to the correct specs. At this point, the hub should be turning freely, with no end float and no pre-load. This was a trial and error process and took a while to complete.

Once I was satisfied that I had the bearings set up correctly, I removed everything, keeping careful track of the shims! I then packed the wheel bearings with wheel bearing grease and installed the front seal. The seal has the spring facing the bearings. I then placed the spacer in the hub extension and bearings in first, and then reassembled unit.

I torqued the nut to the 40-70 lb setting, lining up the hole in the axle with the nut and placed the split pin through the hole in the spindle axle, and then pulled one tab of the pin forward and bent it back over the axle end. I then pushed the grease cap on to the axle ( do not fill it with grease) and gave it a tap with a drift.

Rotor and Hub Install

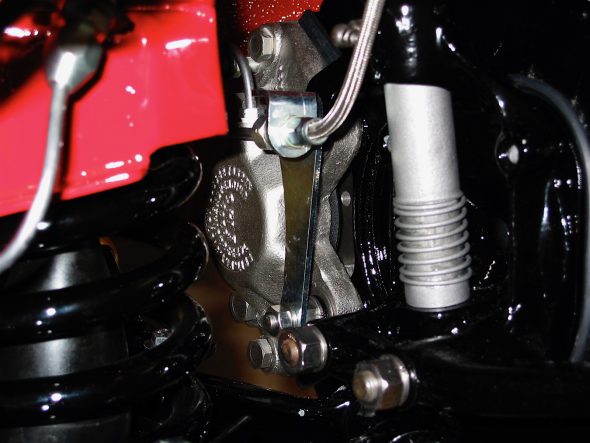

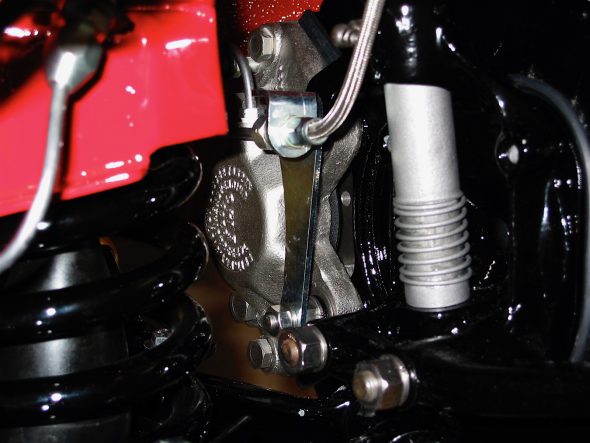

The time has come to install the front brake calipers, the hose brackets and the brake pads. The calipers mount through the brake dust shield and into the swivel axle. My calipers were rebuilt by Healey Surgeons. I used stainless steel flexible brake lines rather than the stock rubber lines.

SS Brake Line RH 2

Brake Caliper

Mintex pads, MGB 520, were used initially, although I may switch to “greenies.” Shims were used between the pads and the pistons with an application of Permatex Ultra Disc Brake Caliper Lube #24110. All hose and pipe fittings were checked and tightened with teflon tape used on all threads.

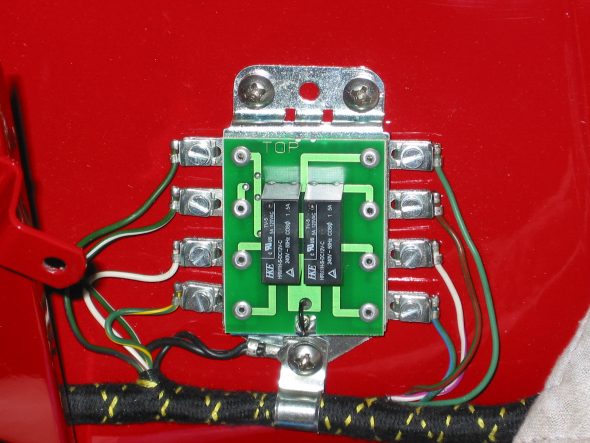

I converted the overdrive relay into a relay for the driving lights. The image to the right illustrates the mounting location, again, using nutserts.

Driving light relay 1