To dress-up the appearance of the boot and to provide a clean surface when carrying clothes or luggage, I had a carpet cover made for my spare tire using carpet to match the interior of The Bloody Beast.Under the cover I still have the leather harness/belt to tie down the tire.

Tag Archives: Boot

Luggage Rack Lexan Boot Lid Shield

I have a Cape International luggage rack on “The Bloody Beast” and I am very pleased with its looks and functionality. One of the features I like best is how closely the rack “hugs” the contours of the boot lid; however, the curvature of the boot lid makes it quite possible for items carried on the rack to rub against the paint with the possibility of ensuing paint damage. This is especially true if you desire to carry something like folding chairs in bags that are not completely flat. To protect the paint I developed the folding transparent (and waterproof) plexiglass shield shown below. The folding joint in the Lexan allows me to fold the glass in half for easy stowage in the boot when not in use.

The hinge folds 180 degrees. Ordered from McMaster-Carr, 11565A11, Clear Acrylic w/White Polyester Middle. Lexan is 1/4” thickness and is quite rigid.

Chapter 20 – Cleaning and Trial Fitting

July 3, 2004

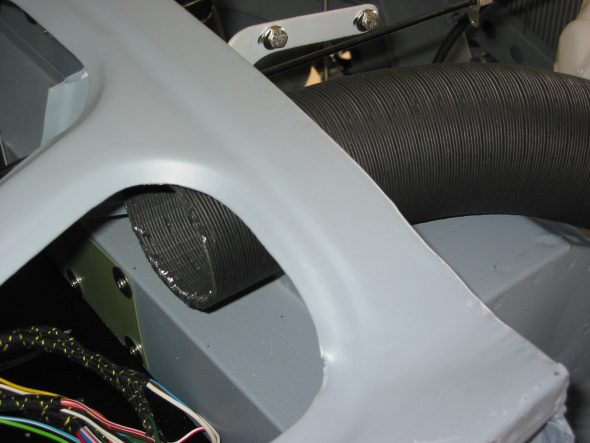

Boot Armacord Liner

Test installed the boot liner material from Heritage. Won’t be gluing it in until after the car is painted. Everything seemed to fit fine and the material looked great.

3M spray adhesive is claimed to work well. Install before fuel tank, but after the fuel tank strap brackets are affixed, and before the battery cable fixture is added and before all wood blocks are secured. Be sure to put holes or cuts in fabric.

Install the cardboard fuel neck cover after the tank and filler pipe – will need to drill three holes after material is glued in.

I reboxed everything and stored it in the coat closet downstairs.

The panel install order is below:

1 Battery cable vertical panel – glue

2 Left wheel well curved panel – glue

3 Left vertical wall panel – glue

4 Right vertical wall panel – glue

5 Left floor well – glue

6 Right floor well – glue

7 Back vertical wal -l glue

8 Rear shroud panel ?

9 Floor Panel – not glued

I didn’t think about getting the hylomar sealant in the fuel tank when I sealed the sender unit gasket. I will need to replace, clean, and reseal more carefully.

Fastened both tapped plates that secure the rear wings to the superstructure to the body temporarily. They may not be in the right location.

Air Control Assembly – Installed the front left air control assembly. It did not fit real well due to some bending done by Martin but after some convincing the job was accomplished.

July 11, 2004

Heater Installation

I purchased a modern replacement for the original Smiths Heater from Cape International. The heater is basically the same footprint, but it incorporates the fan blower making the original fan blower extraneous or irrelevant. The provided mounting plate to the cold air box was installed upside down and backwards which threw me for a minute. After reversing the plated the heater installed nicely using the four #10 x 1/2” original mounting locating screws.

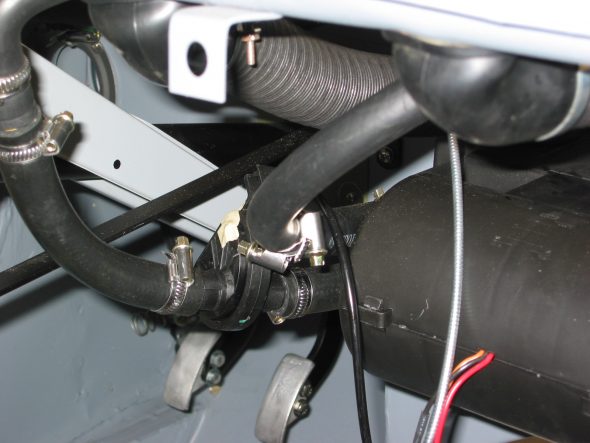

I drilled a slightly larger hole in the included water control valve control arm to permit the installation of a cable connector with tightening screw to secure the wire and cable sheath.

I could not figure out how to connect the water control valve in a way that would permit using the dash control slide knob as originally intended. Instead it works exactly in reverse. Oh well, small price to pay!

Replaced the original cable sheath and wire with a bicycle brake cable for smoother operation of the slide control to the water control valve. Worked nicely.

I received a new Smiths heater blower from Hemphills that proved to be a very nice replica of the old one. I installed a the new blower on the fender superstructure.

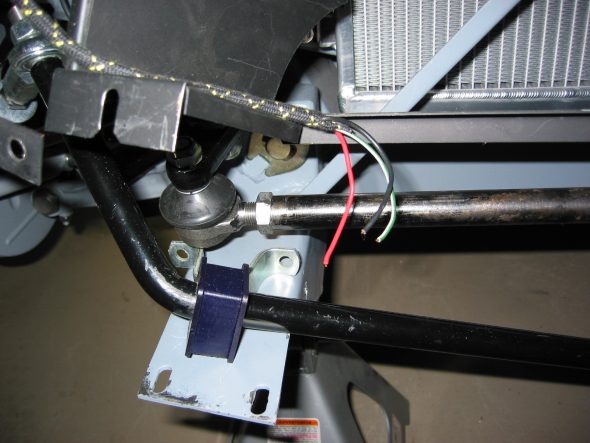

The new blower will now be used to “push” cold air into the passenger side of the interior. I purchased a new air control assembly typically used on the left side of the car. I cut off the mounting flange and inserted it into the ait tube.The right hand knob on the heater panel that used to control the heater can now be used to control fresh air into the cockpit on the passenger side.The cable clamp must be located just as in the photo accessible below the car to get the maximum movement on the air control valve. I need to get some nylon mesh to screen the front air intake. This will give a very “neat” and elegant installation. The cold air will empty just above the parcel shelf in the interior.

I used band hose clamps which cut into the duct hose so when I install the final time I will switch to the wire clamps as used on the car originally. The 4” hose could be approximately 1” longer on final install and the 3” hose could be slightly shorter. I discovered that one needs to clamp the 3” hose to the blower before tightening the blower to the inner fender.

The wiring connections are used as originally fitted. Green and a green/brown wire connect to the two black wires on the dash slide control. The single green wire from the harness connects to the blower on the wheel arch. New wiring and a switch will be added to control the new two speed heater.

Cut the two demister hoses to length and installed them from the top of the heater to the dash superstructure.

Fascia Installation – Fit the fascia to the body. Mounts with four chrome screws and nuts at the corners. One additional screw mounts on the face of the fascia through to the body in the top center. Another locates the brace from the firewall. Upon installation I discovered that the steering column contacted the bottom of the chrome ring surround in the fascia so I moved the column mounting bracket to a higher securing hole on the column brace.

Heater Control Panel

Filed the edges of the control panel very carefully and improved the fit to the fascia considerably.

Blanking Plate – Installed the blanking plate on the right side of the car to cover the master cylinder mounting holes for a RHD car. Used #8 1/2” sheet metal screws into four J nut fasteners. The original plate had tar paper on the back side to seal and insulate, so I will need to do something similar on final install, after the final paint is applied.

Fresh Air Contol Cable – Passenger Side

Drilled the small hole in the firewall next to the tach cable grommet to 5/8” and added a rubber grommet to run the new cool air cable through the firewall.

October 15, 2004

Gearbox Cover and Extension Installation

The original gearbox cover and extension were unusable due to rust. I ordered a new extension panel from Kilmartin and a fiberglass gearbox cover from British Car Specialists. While the cover seemed to be a good fit and will certainly be cooler than the original metal cover, the extension panel did not fit over the Smitty bell housing for the Toyota transmission conversion.

I trimmed the extension panel and then fitted it to the firewall bulkhead. I first placed 1/2” weatherstripping on the bulkhead and then drilled the mounting holes needed – three per side – to secure the panel to the bulkhead. I then drilled two holes in the cover footing to screw it into the frame.

I measured the distance from the metal driveshaft tunnel to the center of the shifter – 13.” Then I installed the cover and measured the same 13” distance and marked it on the cover. I drilled a small hole in the cover just to check the proper location with the shifter. I then drilled a 3 1/4” hole in the center of the gearbox cover for the center shifter. Location was perfect! I used a rubber boot and mounting ring from an MGB as suggested by Smitty. This required drilling 4 small holes for #8 stainless screws.

Now that the gearbox cover was properly located I drilled 4 holes into the frame or floorboard on the right side of the cover and 5 on the left side and fastened the cover to the floor.

I was then able to establish what would become the permanent relationship between the gearbox cover and the extension panel. I measured and drew a template for the floor and measured the distance from the top of the cover to the top of the extension panel – 7 3/8.”

Finally, I recreated the assembly on a piece of 1/2” plywood and secured the panels to the plywood. I added an extra mounting screw on the floor tab of the extension panel to help steady the panel.

Chapter 19 – Cleaning and Trial Fitting

May 28, 2004

Front Splash Panels

Splash Panels – Installed left and right splash panels. I needed to drill 4 new holes on each side of the car in the frame uprights. The left side was difficult and took some hammering and grinding but eventually got it to fit. Use 8 #10 1/2” pan screws to secure.

Radiator Air Deflector – Installed radiator air deflector with two 5/16” x 5/8” bolts.

Bonnet Upright Brackets – Note the way they are mounted in the photos.

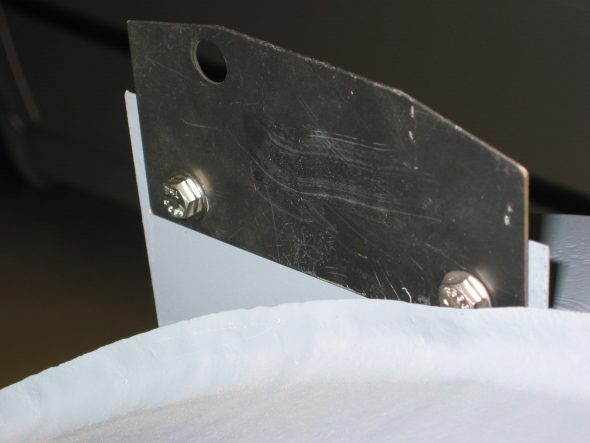

Front Wing Mounting Brackets – Installed left and right front wing support brackets using 4 1/4” x 3/4” hex head bolts.

June 18, 2004

Rear Axle Revisited

Differential – Installed the differential pumpkin and bearing caps in the differential casing. I will be installing the 3.44 crown and pinion in the car when it is drivable, but to get a rolling chassis I just put the old differential back in with no pinion gear. Fastened the differential to the axle and inserted the half shafts and tightened them down with the small locating flat head screws. Affixed the rear brake disc rotors and calipers fastened the hub extensions to the axle with the 5 locking hub nuts.

Installing the Rear Axle – After removing the fuel pump and the left bump box we “walked” the axle with the differential into the chassis and superstructure. I may have been able to leave the fuel pump had we had more access room on the right side of the car, but that wasn’t available. I then secured the axle with the Ubolts and the brackets for the tube shocks. The key here is to start each side loosely and then return to fully tighten each side. I never could get the tube shocks to align with the brackets and Udo Putzke thinks it may be because the Jule frame is slightly different than the original AH frame. To his credit he has agreed to make some longer shaft shocks at cost – great customer service!

Rear Brake Hose – Added the new stainless braided brake hose between the brake line and the rear junction on the axle.

This work allowed me to put the car on the ground as a rolling chassis for the first time – a significant milestone. In honor of the occasion I stuck on two fenders and placed a seat in the interior for photos. All just for fun. It lasted ten minutes and then off came the wheels/tires and wings and then back up on jack stands for more work! The shiny bonnet is a sample paint color that I would ultimately not use.

Driving Light and Tow Brackets – I received the front spotlight and tow hook brackets from Cape International and the rear bumperette (sprite) or Rally Car brackets and “bumpers.” I discovered that Martin Jansen had not included the threaded tubes for the front bumper that go through the frame. Instead Martin’s are only on the outside of the frame rails which is fine for the bumper brackets, but the spotlight tow hook brackets also have one mounting hole on the inside of the frame rails. I located the holes on the inside of the rail with 3/8” drilled hole and will get Jeremy Turner to add threaded tubes later in the restoration. I also received Kilmartin panels for the frame rails that include the welded nuts for the anti-sway bar and I will give them to Jeremy as well.

Horns – Started on the horn installation. The original horns for the Mark I are no longer available so I used the later version. The older horns must have been a little smaller in diameter, because the horns rubbed against the splash panels when connected with the brackets I had. I modified the brackets by adding a mounting hole and grinding off a bit of the bracket to “shift” the horns toward the center of the car. All of this seemed to work flawlessly, but once again I encountered a job that probably should have taken 10 minutes that ended up taking two hours. The horn wiring harness extensions provided by British Wiring were not needed so I crimped some new connectors on the wire in place of the original bullet connectors and attached them to the horns. The new horns were interesting – both brand new – one gloss black and one satin. I will have Jeremy repaint them.

June 18, 2004

Fuel Sender Unit – Installed the fuel sender unit in the new aluminum fuel tank. The sender unit did not line up exactly as the original because the holes in the tank are not as they were in the steel tank. I sealed the sender unit with a new cork gasket and with Hylomar. Each of the small mounting screws received new copper washers.

New Fuel Tank – Secured the new fuel tank with the two securing straps which I had slightly lengthened to make the fit better. The securing straps fastened to the rear boot wall with brackets and clevis pins.

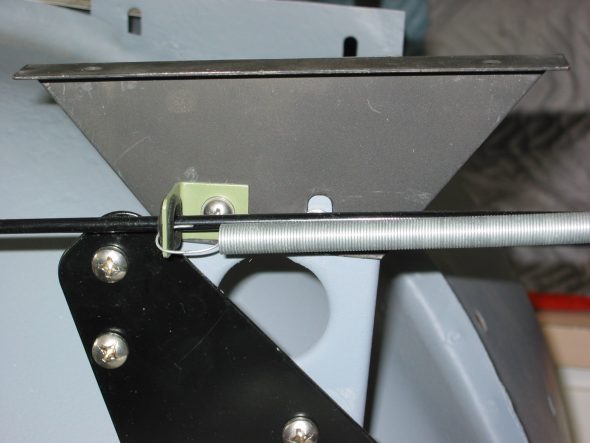

Spare Tire Block and Bracket – Installed the new stainless steel spare tire bracket and tie down bar. I had to make a new vinyl covered block to fit on the back boot wall to accommodate the higher spare tire and the slight rise that was “built in” by Martin Jansen. Turned out pretty well. I actually used old naugahyde from my original reupholstery work on the car 20+ years ago!

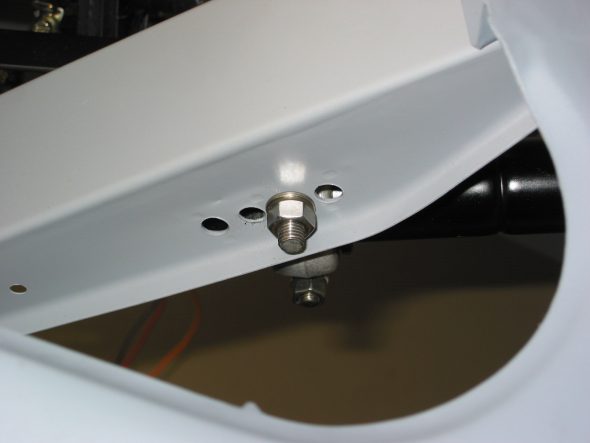

Fuel Filler Pipe – Installed the fuel pipe rubber gasket on the rear shroud. Lightly smeared Vaseline on the lower section of the fuel pipe and pushed it through the gasket into the boot. The Aston Cap is secured to the fuel tube with a threaded brass collar. David Nock advised that I should fasten the collar to the tube by reversing the ends and brazing the collar to the tube’s unfinished end. Then I cut off the old cap end to put into the rubber sleeve to connect to the tank neck.

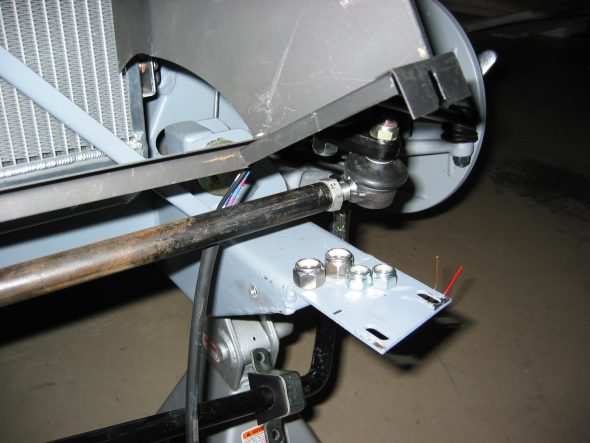

Steering Cross Bar – After discovering that the new cross bar for the steering was for a BJ8 I ordered new ends and installed the original cross rod. I probably could have used the BJ8 bar but it looked like the original provided a little more adjustment which I think I needed.

Chapter 7 – Disassembly

Front Shroud

Removed five cross head drive screws at the rear of the bonnet. Three screws with nuts must be removed at the front of the shroud at the bonnet opening. Two cross head screws and nuts also attach the shroud to upright posts. A third bolt and nut holds the prop rod bracket. Five pop rivets were drilled out along the scuttle. Two additional rivets must be drilled out along each side and where the rubber seal attaches to the scuttle. Two bolts securing the shroud to each frame extension in the front must be loosened from their nuts. The shroud can then be released from the rear and pulled forward.

Rear Body Panel (shroud)

The rear body panel is released by first drilling out 19 rivets along the lower lip. Thirteen rivets must be drilled out that hold the body panel to the luggage compartment frame. Two or three rivets must be drilled out on the side of the rear body panel where the wing fastens to it. Four cross head screws and nuts must be removed from the top lip of the boot opening. The rear body panel can then be removed. Care must be taken to not bend the small front lip on the aluminum panel at the front points.

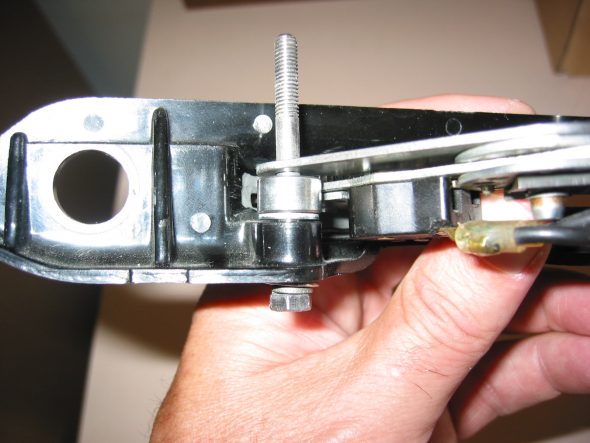

Doors

Removed three posidrive screws holding the interior door handle. Removed four posidrive screws at rear of door by handle. Removed opening mechanism. Loosen phillips head screw in door handle accessible when the door handle is pulled. 5/16” nut on the door handle screw. Loosen 5/16” nut on the screw on the back of the door handle – not easy to get to! Door handle can then be extracted from the door.

Removed side curtain bezel and retaining nut and chrome washer. Removed mid-door wood strip. One pozidrive screw on top center and two screws to the left and right on the bottom side. Removed the door strap (catch).

Remove door hinges. Four bolts into a securing plate for each hinge. Drilled small indentation into the top bracket to recognize it. On reassembly of doors mount outside door handle first. Then install mechanism so that the action arm is in the proper place.

Boot Lid

Removed two screws and cup washers securing the handle/lock. Remove four bolts/nuts holding the lock/catch mechanism. Remove one screw holding the locking mechanism post. Lock surface was painted as were the screw tops so it was installed when the car was painted. The chrome lock and handle were installed after the car was painted because the locking post screw was not painted.

Removed the large cotter pin holding the rubber boot lid support rod. The rubber could then be removed as well. The head of he pin was located on the rod locator bracket side. A small cotter pin was removed from the support rod at the home bracket. The rubber grommet was then removed and the rod was detached.

Removed rubber gasket sealing boot lid.

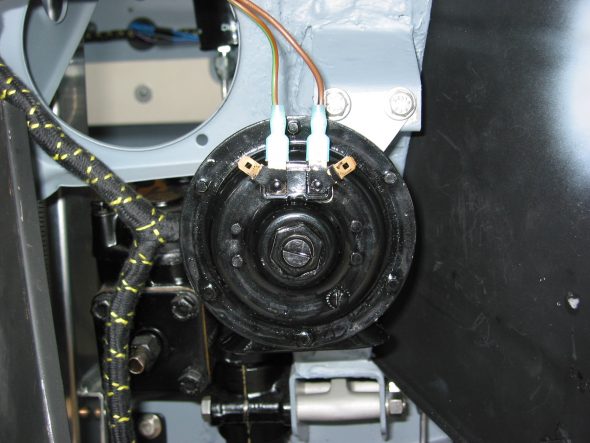

Heater Blower Assembly

Removed four nuts on posts through rubber grommets. Black ground wire connects to the angle pillar. Power is through a green wire with a brown stripe that plugs into a rubber junction.

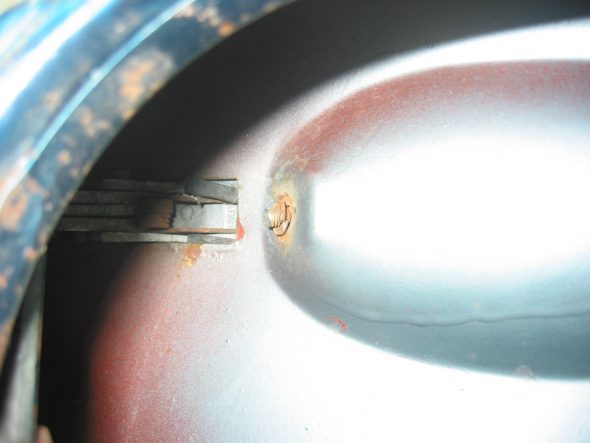

Removed the two heater blower mounting brackets. Two bolts each through wheel well arch. Large washers used on the tire side of the arch.

July 28, 2002

Under Bonnet Components

Horns – Located on the left and right of center under the front shroud. Each horn is secured with two bolts fastened into small steel threaded plates. I don’t believe my horns or brackets to be correct as one was mounted on the vertical shroud support like later cars.