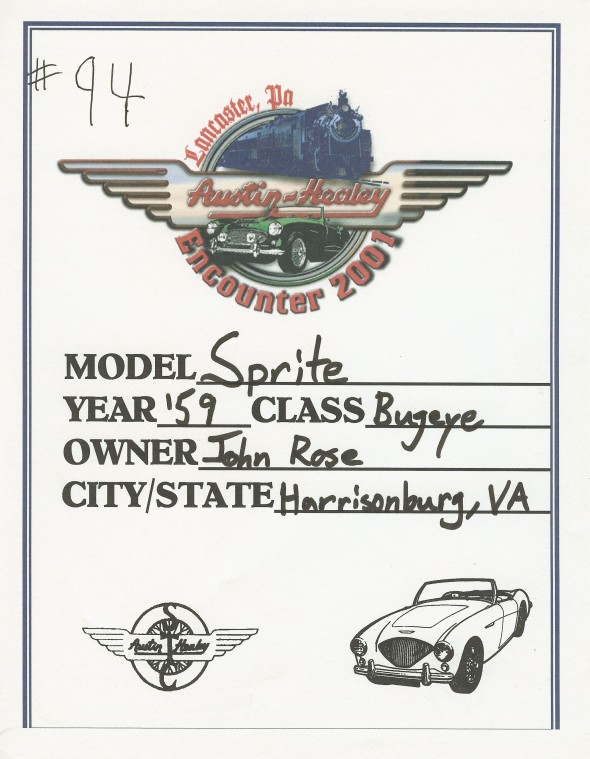

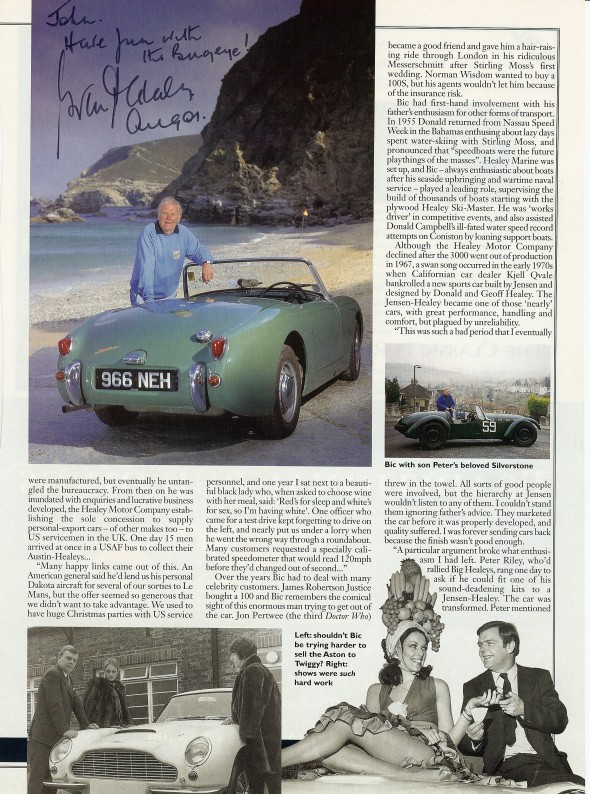

Dad and I drove the Bugeye to Lancaster, PA for Encounter in 2001. I got to meet Bic Healey, Donald’s youngest son, and he autographed a photo of his Bugeye from a Sports and Classics magazine article for me.

Category Archives: Bugeye

Engine Improvements

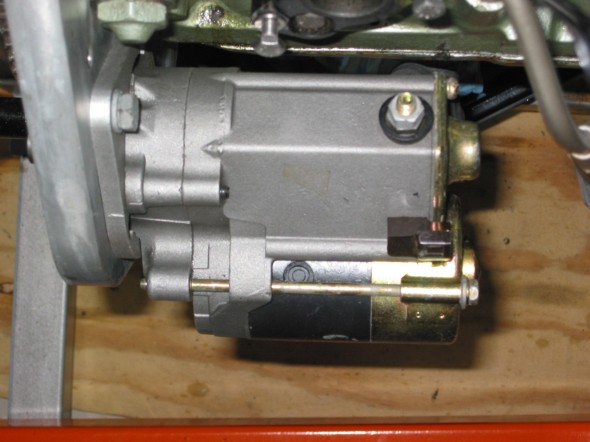

Gear Reduction Starter

Replaced the starter with a modern gear reduction starter from APT Fast. Unlike the old Lucas starter it cranks until the motor fires. Definitely more difficult to install than the original, but hopefully easier starting will make it worth it. Fastening the lower bolt was accomplished by jacking up the right front, removing the tire and wheel and reaching through the hole in the frame wall. The cranking sound is very different than the Lucas starter, but functionality is substantially improved. We chose to continue to use the old pull starter switch on the dash, but could have hooked up the starter to a modern solenoid as well.

2001 British Car Day, Bowie, MD

The 2001 Capital Area Classic

Dad and I attended the Capital Area Austin Healey Club father-son weekend meet at Frederick, MD. It was the first time that I had participated in a show or club event with my Bugeye, so it was pretty exciting. The car broke down in Berryville. After getting fuel it just wouldn’t start again. Turned out to be the starter, but substantial consternation involved before things got fixed by the next day. I participated in my first Funkhana and actually won it!

I came in second in the popular judging show. Highlight of the event was that Gary and Paulette Lownsdale, The President of the Austin Healey Club of America attended. I drove the Bugeye home from Frederick – about 2 hours.

Engine Enhancements

The car is running a little rich. I attempted to adjust which became an experience. As the book says, I backed off the jet adjusting nuts 11 flats only to find that the car would not start at all. After a little help from the midget/sprite email list, I backed off the jet nuts one flat at a time until I got to 24 flats before the car began to run well. However, now it runs better than ever.

The car is running a little rich. I attempted to adjust which became an experience. As the book says, I backed off the jet adjusting nuts 11 flats only to find that the car would not start at all. After a little help from the midget/sprite email list, I backed off the jet nuts one flat at a time until I got to 24 flats before the car began to run well. However, now it runs better than ever.

Hayden Electric Fan

The car is running slightly hot (past normal temp) with just the hayden electric fan. Dad decided to put the 6 blade plastic fan on as well. The two together work effectively. Now we seem to be staying well within acceptable temperature range. I had tried to save the horsepower used by the water pump fan, but oh well.

Electronic Ignition

We installed a Crane XR-700 electronic ignition and had the timing, valve clearances checked by Jack Harper at Coach Works. This is the installation manual for the Crane Electronic Ignition: Crane XR700 Installation Instructions

Began installation of the electronic thermostat for the electric fan, but decided against it. Will just switch it on manually when needed. It’s a little noisy!

Making The Bugeye “My” Bugeye

I ordered new Panasport 13 x 5″ wheels. I paid for the wheels and Dad paid for the tires – 185 x 13 70 Bridgestones. The tire selection turned out to be a mistake, they were too big and rubbed the bonnet when the wheel turned.

We ended up replacing the Bridgestones with Wynstar 185 x 13 60 lower profile tires which worked fine. Unbelievable difference in the handling for the car – it really sticks to the road now. Needed to order new lug nuts for the Panasport wheels as original equipment didn’t work with the wheels.

Hayden Electric Fan

Installed a 10″ electric fan to replace the plastic stock fan. Required fabricating some metal brackets to mount the fan, rather than using the plastic mounting screws provided with the fan. It’s better to have the fan pull rather than push air, but that won’t work with the bugeye because the fan won’t fit on the engine side of the radiator. Installed the fan with an on-off switch at the dash but will replace it with an automatic thermostat to control fan operation.

Intake Manifold

Located a used stock intake manifold. Installed it and eliminated the problem with the carbs hitting the bonnet when closed.

Conversion to Front Tilt Bonnet

Purchased a front hinge kit from Minimania. Good kit that included complete instructions, hinges, cable restraints, brackets (although the cables were too short), and wiring. Removed original back body hinges, and latching mechanism at the front of the bonnet.Mini Mania FRONT- MOUNT HINGE KIT FOR BUGEYE SPRITE

- Clip headlight wire harness 16″ from passenger side blinker.

- Remove bonnet

- Remove telescopic bonnet catches

- Remove grill (13 retaining clips)

- Remove bonnet handle

- Remove two locating pins for bonnet

- Install support cable bonnet securing plates – 2 to bonnet installed by pop rivets and 2 on radiator mounting brackets

- Remove bonnet hinges – a long bolt and nut reached under the dash.

- Remove bonnet safety catch/latch

- Remove latch locator plate

- Install stainless steel bolts for new bonnet securing springs.

Fabricated hold-down spring brackets using a conduit clip, spring and stainless steel bolts. This approach, copied from John Carey’s web site works great and is much less visible than rubber or leather straps on the side of the body. The front hinge set-up does not permit use of the front bumper. This assembly is made from a galvanized conduit wall clip slightly bent closed and attached to a zinc plated spring. It is covered with a black plastic wiring harness cover so as not to be too obvious in the dark wheel well. The small stainless bolt is installed thru an existing hole in the bonnet (top of spring – left).

You must use nuts on both inner and outer sides of the bonnet to hold it firm in the position shown. You can crank the wheels out of the way and quickly clasp the conduit clip under the floorpan lip (lower at left) then stretch the spring up until it grabs the head of the stainless bolt. The position is perfect to hold the bonnet down and in against it’s intended rubber stops… This eliminates drilling to install and works great even in HEAVY cornering and bumping along back country roads. It is also as quick or quicker than leather buckles to open and close.

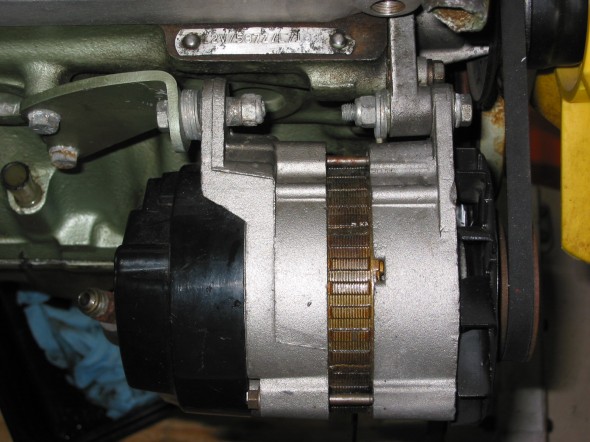

Conversion from Dynamo to Alternator

Removed the dynamo and installed a lucas alternator. Required reworking wiring and eliminated the need for the voltage control box. Referred to directions from Larry Miller and John Carey for wiring help. Seems to work well and should be a bonus if we ever add driving lights, halogens, radio and etc. A new fan belt was required for the alternator that is shorter than the belt used for the dynamo.

Removed and discarded large yellow wire from terminal D on the voltage regulator box to the dynamo. It is no longer needed.

Removed black ground wire from terminal E on the voltage regulator box to the dynamo. It is no longer needed.

Removed black wire from terminal F on the voltage regulator box to the dynamo. It is no longer needed.

Connect brown wire from alternator (middle spade) to battery post terminal.

Connect small yellow wire from speedometer warning light that originally went to terminal D on the voltage regulator box to the small spade on the alternator.

Connect large yellow wire from ignition switch that originally went to the A1 terminal on the voltage regulator box to the baby blue wire to the remaining large spade on the alternator, and to the purple wire from the fuse panel. These 3 wires are soldered together.

Collect wires and plug connector into the alternator.

Installing the 1275 Motor

The engine and gearbox were purchased from Rivergate Restorations. After driving the Bugeye on the Washington Beltway to bring it home the first day, Dad and I knew that we would have to get some additional horsepower in the Sprite. The Rivergate setup was just perfect. We were very pleased with the product and the service.

The engine numbers 12V/587Z/L7183. This engine was sourced from either an Austin-Healey Sprite, MK4 or from an MG Midget, MK3. The 587 engine was produced for North American Sales and was apparently rather rare in the States, so it may have been a Canadian car. The “L” stands for low compression, that is 8.0:1. The engine was produced from 8/1971 to 8/1972. The engine, as produced at the time, would have been painted black.

Installed engine and transmission. Reverse of removal process. Unfortunately we got the engine mounts reversed and backwards which resulted in a great deal of frustration in seating the engine. Finally with a little outside help we corrected the problem and the engine went in like a charm. It did require a little beating with a hammer on the plate below the heater box so that the transmission would clear. Of course, the header and carbs had to come off the engine before placement in the engine bay.

Bill Perry, from Rivergate, provided installation instructions that proved to be helpful. Rivergate Engine Installation Instructions 2000

Rivergate also provides a comprehensive instruction manual for the installation of the Datsun B210 5 speed transmission. Because we purchased the transmission and installation kit with the transmission already mounted to a rebuilt MG Midget engine that we also purchased from Rivergate, much of what is described in the kit installation manual was already done by Bill and/or Will Perry. The annotations in the margins of the instruction manual indicate the previously accomplished work. Rivergate Installation Instructions 5 speed Transmission Conversion Kit 1999

A link to the shop manual for the Datsun Gearbox is provided below in case maintenance is needed at a later date:

Installed new heater water valve in head – used cap screws instead of studs.

Installed thermostat cap

Installed new water drain tap to block

Discovered that we needed a 1275 yellow plastic 6 blade fan along with a spacer so that the blades will clear the breather on the timing cover – frustrating!

Installed generator. Will convert to the alternator after we get the motor working properly at a later date.

Put 2 1/2 pints of Valvoline synthetic gear lube in the transmission. This required a long length of clear plastic tubing to the transmission fill hole on the driver’s side of the tranny.

Installed new intake manifold from MiniMania and new carbs from Moss. We later discovered that this manifold sat too high and resulted in a dented bonnet. It had to be replaced with a stock unit.

Installed new oil filter and filled the engine with oil – 30 weight real oil for break-in. 4 1/2 quarts.

Put a little carb damper oil in each carburator.

Bled the brakes and the slave cylinder for the clutch.

Installed new fan blade with spacer and radiator.

Reconnected oil pressure line

Reconnected water temperature gauge.

Installed driveshaft. Beat the universal joints unmercifully and they finally came apart. Installed the new ones supplied by Rivergate.

Connected the speedometer cable.

Checked fan belt tension

Installed exhaust system which required fabricating a bracket for the rear mount.

Reattached the engine ground cable.

Installed a leather shift boot from a later model midget so that the datsun B210 shifter lever would fit a little better, rather than using the original metal boot.

Adjusted clutch slave cylinder pushrod

Installed new SU fuel pump in the engine compartment rather than at the rear bulkhead and ran fuel line to the carbs. This approach is not recommended, but everyone who has done it says that it has worked fine for them. The theory is that it gets too hot in the engine compartment, but others suggest that it is cool enough at this location. The mounting bracket is the same one used at the rear of the car. It is just bent to fit with nylon spacers.

Reconnected battery, generator, distributor and other electrics.

Poured a little oil down the banjo bolt to lubricate the oil pump.

Attempted to start the car, but it failed to fire. Had the car towed to Coachworks. We had set the carbs too lean to fire! After minor carb adjustment, and timing the car started and ran well.

Installed the bonnet and bumper. Discovered that the MiniMania intake manifold made the carbs sit too high. The carbs dented the bonnet when one of my friends attempted to force shut the bonnet by standing on the bumper.

Removing The 948

Having decided to purchase a 1275 motor and Datsun B210 gearbox from Bill Perry at Rivergate Restorations we worked hard the week of July 4 to remove the 948 and to get ready for the 1275. We also did some interior and electrical work under the dash fascia. By the end of the week, we were ready for a new engine and gearbox.

Disconnected wiring harness to the bonnet lights. Electrician’s tape on two exposed connectors.

Bonnet removal:

Remove passenger side catch brace

Remove two back hinge screws on each side of bonnet

Remove driver side catch brace

Remove two front hinge screws on each side of bonnet

Lift bonnet off car from the sides

Remove front bumper

Remove heater duct

Jacked-up car and placed on 4 stands

Removed front wheels

Drained radiator

Removed radiator – 4 bolts – loosen hoses

Disconnected heater hoses

Disconnected coil connection

Removed copper heater pipe to get to intake manifold bolts

Removed throttle cable from throttle shaft (rear)

Removed choke cable from two arms at carbs (front)

Drained transmission fluid

Removed motor ground cable

Removed exhaust pipe bracket from rear of engine plate

Disconnect fuel line from carbs

Removed the vacuum line connected at front carb

Removed carbs in masse from the intake manifold

Removed exhaust pipe and muffler in one piece

Disconnect fuel lines to/from the fuel pump

Removed generator and fan belt

Disconnect speedometer cable from transmission

Disconnect starter motor battery cable

Disconnect red wire to distributor from the coil (wentworth)

Disconnect oil pressure line from block

Disconnected water temperature sending unit from block

Disconnect driveshaft at rear – four bolts – order new ones

Transmission: remove shift lever cover – 4 screws

Remove shift lever – lubricate on reinstall – 7/16” bolt n side first, then three 7/16” on top.

Remove two large bolts on side of transmission tunnel

Remove two large bolts underneath the car securing transmission mount

Disconnect front motor mounts: Remove three bolt on driver side engine mount

Remove two nuts on passenger side rubber motor mount, also removed one 9/16” nut on rubber motor mount

Used “Peeler” aerosol paint remover on the radiator and the heater box. Worked great.

Removed heater assembly – Four large phillips head screws and then slide off to the right.

Disconnect heater valve cable.

Remove heater blower – black ground wire with blue tip and circle clip to body. Black wire to green with red stripe.

The choke cable is fastened to one of the heater body clamps with a plastic tie on the right side of the heater

Painted heater box with rustoleum primer and black gloss paint.

Removed fascia – 3 7/16” bolts, one on each corner, one in the middle; plus two phillips head screws to two support bracket.

Disconnect tach and speedo cables

Disconnect white plastic clamps on left wall holding the water temp. sending unit – one clamp is shared with the battery ground cable.

Disconnect the oil pressure pipe at the joint so that it can be pulled through the dash rubber seal along with the water temp unit

Disconnect the starter cable from the solenoid

Remove wiper motor – 3 nuts in footwell, and four nuts to remove wiper cable.

Disconnect the two wiper boxes by loosening two screws on each which then permits removal of the wiper cable

Wiper motor electrical connections: green wire on top, Blue below it and Black to the side

We rented an engine hoist and removed the 948 and gearbox.

Safety Check & Rivergate Modifications

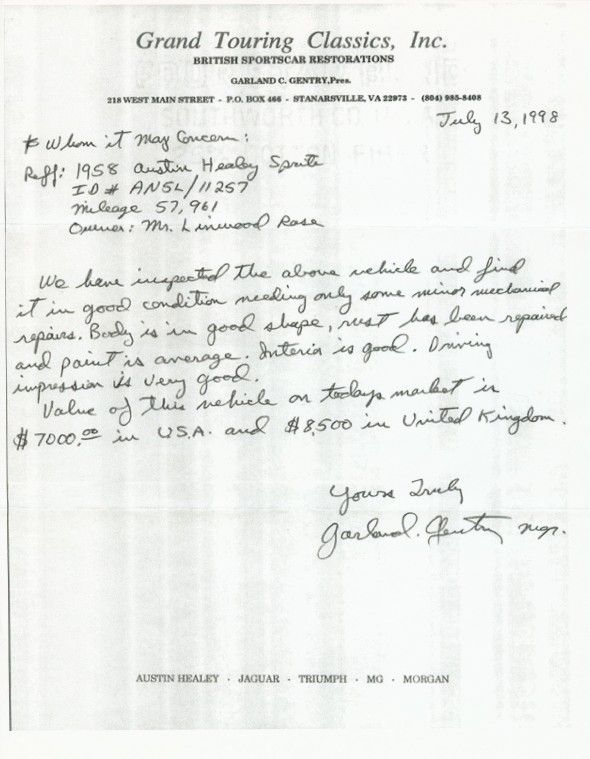

The week after we got the Bugeye home, Dad took it over the mountain from Harrisonburg to Grand Touring Classics in Stanardsville, VA. An unlikely place for a British car shop, but they seemed to know Healeys and were in the process of restoring a Bugeye. Garland Gentry ran the shop and was willing to give the Sprite a good going over to make sure it was safe to operate. Engine compression was good but it was in need of some minor mechanical work. Dad asked Garland to prepare an insurance appraisal of the car and it is found below:

We had read that converting the drum brakes on the front of 948 Bugeye to disc brakes from a later Sprite or MG Midget was pretty straight foward. Dad didn’t have the time to make the conversion so he had Garland go ahead and get the parts and install the upgrade. As things turned out, the brakes worked a little too well. Garland had forgotten to remove the check valve from the master cylinder and consequently the rear brakes kept locking up and overheating. After making some calls and emailing some sprite owners, Dad figured out the problem and took care of it. Brakes were much improved but still not as good as hoped. We would later find out that the 1098 Sprite with disc brakes used a 3/4” bore master rather than the 7/8” found in the earlier bugeye.

So the disc brake conversion became the first of many “improvements” to the Bugeye that we would make. We knew after driving the Sprite on the Washington Beltway with the big trucks passing us, that conversion to a 1275 motor and a Datsun B210 gearbox wouldn’t be far behind.

If one was sourcing a gearbox, the following guidance is provided by Rivergate:

Sprite/Midget 5-Speed Kit Transmission Required

The serial number on top of the bellhousing should begin with the letter “F” (FL, FA, FX etc. OK).

The number “60” is cast into the right side of the main case. These transmissions come from the Datsun 210, but the model number for these cars, imbedded in the Serial Number, is B310.

The model number for the transmission, FS5W60A, is sometimes found on the Serial Number plate on the firewall. This is not found on the transmission.

When the transmission is bought, the gearshift lever, throwout bearing carrier and clutch release fork are needed.

The Rivergate Five Speed Conversion Kit includes:

Instructions, detailed, with color photos for clarity

This is the most complete, easiest to install kit ever made for the Spridget. It requires no modification to the engine, the flywheel, the driveshaft, or to the chassis or body of your Sprite or Midget.

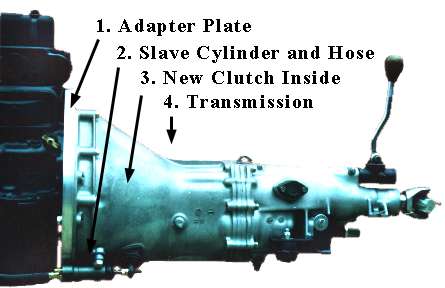

1. Adapter Plate: Machined from 6061 Aluminum billet. All tapped holes have helicoil inserts. Attractive and precision. Replaces original steel plate. The plate includes a rear crankshaft seal integrated into the design.

2.Clutch Slave Cylinder and Hose: You may use the original slave cylinder presently on your Spridget or the billet aluminum cylinder with stainless steel braid covered Teflon hose we offer.

3. Inside: New clutch disc that works with stock pressure plate. No mods to flywheel. New pilot bushing included.

4. Transmission: Five speed overdrive, all synchronized. From 1979-82 Datsun 210. Buy locally or from sources listed here. Expect to pay around $200.00 — maybe less.

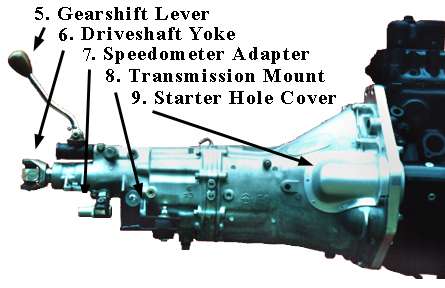

5. Gearshift Lever: Shorten it to match length of stock lever. Will use either 5 speed knob or stock Spridget knob.

- Driveshaft Yoke: Installation of yoke and U-joint adapts driveshaft without any cutting or modification.

- Speedometer Angle Ratio Adapter: Part of Angle Ratio Adapter and Speedometer cable kit. Custom geared to match the rear end ratio and tire circumference on your car. Corrects speedometer reading and makes cable installtion easier and more reliable. Optional item.

- Transmission Mount Assembly: Bolts in like stock unit, with bolts up through the crossmember. Utilizes six durometer 40 pads.

- Starter Clearance Hole Cover: An optional item, primarily for appearance. Only needed for kits purchased before September 2000.

A Rear Crankshaft Seal System was installed in the 1275 motor we purchased. Rivergate had developed a rear crankshaft seal for Sprites & Midgets. The seal system uses a spring backed neoprene seal, and is incorporated into the aluminum transmission conversion adapter plate. It applies to 948, 1098 and 1275cc engines. No engine teardown nor modification is required for installation, but the engine must be out of the car. It is designed to stop oil leaks at the rear of the engine whether they are from around the crankshaft itself, or if the leak is thru the machined surface between the block and the rear main bearing cap.

The crankshaft seal arrangement is furnished with a tube of special aluminum sealant. In addition to use with the seal, it is large enough to use to seal the adapter to the back of the engine block and the oil pump cover into the adapter plate.

The crankshaft seal requires a specially machined 5 speed conversion kit adapter plate. The plate is furnished as part of the conversion kit. In addition, Rivergate can re-machine any of our adapter plates built since February of 1996 to accept the seal kit. See the price list for information.

Also available is the service of machining the standard Rivergate adapter plate to allow for installation of the Bolt-on rear crankshaft seal available from several of the Spridget and Mini Vendors.

The following specifications describe the rebuilt engine purchased from Bill Perry at Rivergate.

Rebuilt 1275cc Sprite/Midget motor, bored .030″ over to give 1301cc.

Includes:

Prepared 1275 Engine

Bored .030″ oversize

Pistons – modern 3 Ring, High Compression

Rod, Main, Thrust Bearings

Oil Pressure Release Valve and Spring

All Gaskets, Front Seal and Valve Stem Seals

Water Pump

Oil Pump

Cam – choice of 266 or 276 Kent Performance Cam

Cam followers

Valve Springs – Upgraded Quality

Timing Chain

Valve Guides

Thermostat

Pricing

Rebuilt 1275cc Sprite/Midget Motor $2,450.00

Balance all Rotating & Reciprocating Parts $125.00

Lighten flywheel – modest lightening for street use $50.00

Aluminum Cylinder Head – Improved flow and performance, Stellite valve seats, 19 pounds lighter than stock, ready for no-lead fuel, bronze valve guides – a beautiful, functional addition to Sprite/Midget – $725 price only applies to a cylinder head purchased with a rebuilt motor.

Additional Options:

New Pressure Plate – should be purchased if balance option is chosen, so it can be balanced with all other rotating parts $69.00

Camshaft – Scatter Pattern SPVP3 or SPVP4, your choice, (others available) $90.00

Convert to 11 studs – Requires Aluminum Cylinder Head and ARP studs $75.00

Tubular Chrom Moly Pushrods $69.00

Convert to use unleaded fuel — bronze valve guides & Stellite valve seats & valves $140.00

ARP Fasteners

Very high quality fasteners as used on most Spridget Race Motors:

Head Stud Set, includes rocker studs $125.00

Main Stud Kit $70.00

Flywheel Bolt Set $18.00

Rod Bolt and Nut Set $106.00

SHIPPING:

Shipped in custom crate which must be promptly returned.

Crate Core Charge is $125.00 (will be applied to orders when billed and refunded when the crate is returned) $125.00

Crating Charge $35.00

Shipping (actual cost) $120.00 to $450.00

If engine is purchased along with a five-speed overdrive conversion kit, the engine will be assembled with the aluminum adapter plate rather than the stock iron rear plate.

Purchase Day

Following vacation, we stopped in College Park, Maryland and conducted final negotiations with Tom Delaney for the purchase of my Bugeye. We started it up and drove around the neighborhood and decided to buy the car. The brakes were not great and it certainly wasn’t fast, but it looked so cool! Of course, I could not drive yet because I didn’t have my license, but it wasn’t hard to imagine the fun I would have in the future.

Not long after we got the Bugeye home, Pap-Pap and Grandma visited us and got to share in the fun!