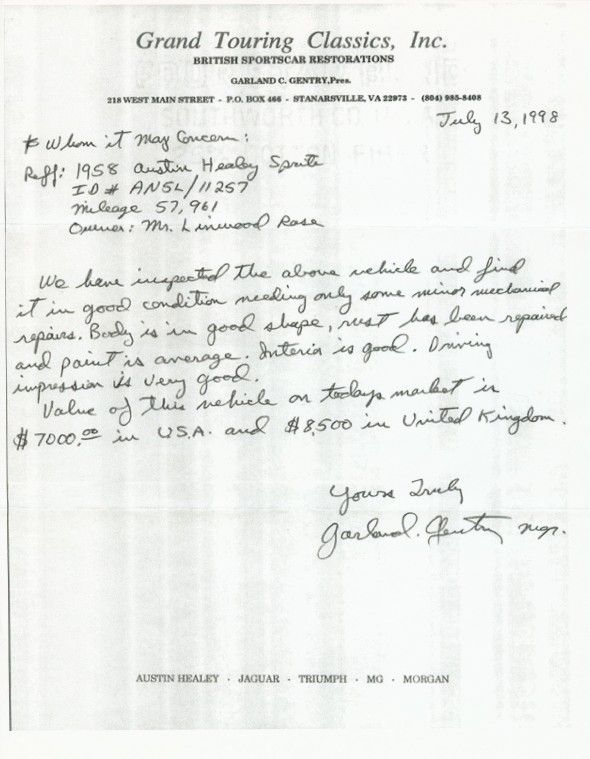

The week after we got the Bugeye home, Dad took it over the mountain from Harrisonburg to Grand Touring Classics in Stanardsville, VA. An unlikely place for a British car shop, but they seemed to know Healeys and were in the process of restoring a Bugeye. Garland Gentry ran the shop and was willing to give the Sprite a good going over to make sure it was safe to operate. Engine compression was good but it was in need of some minor mechanical work. Dad asked Garland to prepare an insurance appraisal of the car and it is found below:

Appraisal

We had read that converting the drum brakes on the front of 948 Bugeye to disc brakes from a later Sprite or MG Midget was pretty straight foward. Dad didn’t have the time to make the conversion so he had Garland go ahead and get the parts and install the upgrade. As things turned out, the brakes worked a little too well. Garland had forgotten to remove the check valve from the master cylinder and consequently the rear brakes kept locking up and overheating. After making some calls and emailing some sprite owners, Dad figured out the problem and took care of it. Brakes were much improved but still not as good as hoped. We would later find out that the 1098 Sprite with disc brakes used a 3/4” bore master rather than the 7/8” found in the earlier bugeye.

So the disc brake conversion became the first of many “improvements” to the Bugeye that we would make. We knew after driving the Sprite on the Washington Beltway with the big trucks passing us, that conversion to a 1275 motor and a Datsun B210 gearbox wouldn’t be far behind.

Dad contacted Rivergate Restoration about purchasing their conversion kit to the Datsun transmission. After talking to Bill Perry it was decided that a rebuilt 1275 and a rebuilt Datsun B210 gearbox would be purchased as an assembled unit. The Rivergate folks are great to work with.Their contact information is below:

Rivergate Restoration Products

340 Reavley Road Sale Creek, TN 37373

423-332-2030 (Fax: 332-6914)

rivergate5speed@bellsouth.net

If one was sourcing a gearbox, the following guidance is provided by Rivergate:

Sprite/Midget 5-Speed Kit Transmission Required

A Datsun 5-speed transmission from August 1979 to 1982 Datsun 210. This can be from a coupe, sedan or wagon.

The input and output shafts should be 20mm (about 25/32″) diameter and 18 spline.

The serial number on top of the bellhousing should begin with the letter “F” (FL, FA, FX etc. OK).

The number “60” is cast into the right side of the main case. These transmissions come from the Datsun 210, but the model number for these cars, imbedded in the Serial Number, is B310.

The model number for the transmission, FS5W60A, is sometimes found on the Serial Number plate on the firewall. This is not found on the transmission.

When the transmission is bought, the gearshift lever, throwout bearing carrier and clutch release fork are needed.

The Rivergate Five Speed Conversion Kit includes:

An aluminum adapter machined from a billet of 6061 aluminum

A rear crankshaft seal fitted to the adapter plate to help eliminate oil leaks

A rear motor mount assembly (with 6 durometer 40 pads built in)

A new clutch disc to be used with the standard pressure plate

A pushrod assembly and spacer for the slave cylinder

A plug for the transmission case

A 5/8″ and 3/4″ pilot bushing

Forty bolts and washers for attaching the adapter plate and the transmission

New driveshaft yoke with U-joint installed

Throw-Out Bearing

Rear Transmission Seal

Clutch Alignment Tool

Instructions, detailed, with color photos for clarity

This is the most complete, easiest to install kit ever made for the Spridget. It requires no modification to the engine, the flywheel, the driveshaft, or to the chassis or body of your Sprite or Midget.

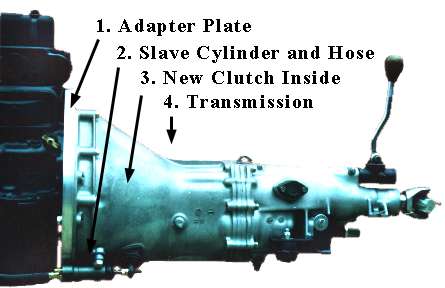

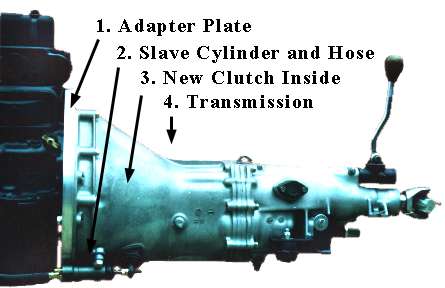

Modification Kit Side 1

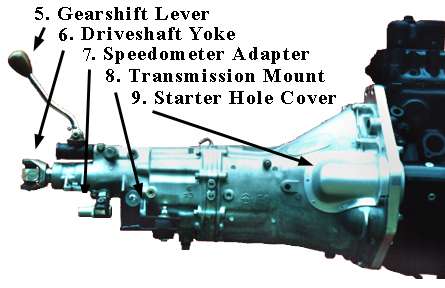

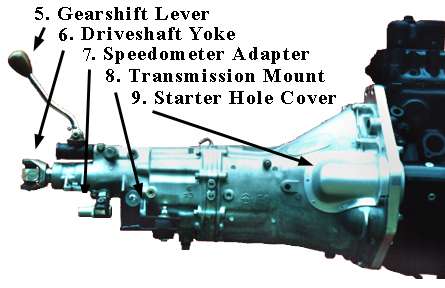

Modification Kit Side 2

1. Adapter Plate: Machined from 6061 Aluminum billet. All tapped holes have helicoil inserts. Attractive and precision. Replaces original steel plate. The plate includes a rear crankshaft seal integrated into the design.

2.Clutch Slave Cylinder and Hose: You may use the original slave cylinder presently on your Spridget or the billet aluminum cylinder with stainless steel braid covered Teflon hose we offer.

3. Inside: New clutch disc that works with stock pressure plate. No mods to flywheel. New pilot bushing included.

4. Transmission: Five speed overdrive, all synchronized. From 1979-82 Datsun 210. Buy locally or from sources listed here. Expect to pay around $200.00 — maybe less.

5. Gearshift Lever: Shorten it to match length of stock lever. Will use either 5 speed knob or stock Spridget knob.

- Driveshaft Yoke: Installation of yoke and U-joint adapts driveshaft without any cutting or modification.

- Speedometer Angle Ratio Adapter: Part of Angle Ratio Adapter and Speedometer cable kit. Custom geared to match the rear end ratio and tire circumference on your car. Corrects speedometer reading and makes cable installtion easier and more reliable. Optional item.

- Transmission Mount Assembly: Bolts in like stock unit, with bolts up through the crossmember. Utilizes six durometer 40 pads.

- Starter Clearance Hole Cover: An optional item, primarily for appearance. Only needed for kits purchased before September 2000.

A Rear Crankshaft Seal System was installed in the 1275 motor we purchased. Rivergate had developed a rear crankshaft seal for Sprites & Midgets. The seal system uses a spring backed neoprene seal, and is incorporated into the aluminum transmission conversion adapter plate. It applies to 948, 1098 and 1275cc engines. No engine teardown nor modification is required for installation, but the engine must be out of the car. It is designed to stop oil leaks at the rear of the engine whether they are from around the crankshaft itself, or if the leak is thru the machined surface between the block and the rear main bearing cap.

The crankshaft seal arrangement is furnished with a tube of special aluminum sealant. In addition to use with the seal, it is large enough to use to seal the adapter to the back of the engine block and the oil pump cover into the adapter plate.

The crankshaft seal requires a specially machined 5 speed conversion kit adapter plate. The plate is furnished as part of the conversion kit. In addition, Rivergate can re-machine any of our adapter plates built since February of 1996 to accept the seal kit. See the price list for information.

Also available is the service of machining the standard Rivergate adapter plate to allow for installation of the Bolt-on rear crankshaft seal available from several of the Spridget and Mini Vendors.

John’s engine1275-1

John’s engine1275-2

The following specifications describe the rebuilt engine purchased from Bill Perry at Rivergate.

Rebuilt 1275cc Sprite/Midget motor, bored .030″ over to give 1301cc.

Includes:

Prepared 1275 Engine

Bored .030″ oversize

Pistons – modern 3 Ring, High Compression

Rod, Main, Thrust Bearings

Oil Pressure Release Valve and Spring

All Gaskets, Front Seal and Valve Stem Seals

Water Pump

Oil Pump

Cam – choice of 266 or 276 Kent Performance Cam

Cam followers

Valve Springs – Upgraded Quality

Timing Chain

Valve Guides

Thermostat

Pricing

Rebuilt 1275cc Sprite/Midget Motor $2,450.00

Balance all Rotating & Reciprocating Parts $125.00

Lighten flywheel – modest lightening for street use $50.00

Aluminum Cylinder Head – Improved flow and performance, Stellite valve seats, 19 pounds lighter than stock, ready for no-lead fuel, bronze valve guides – a beautiful, functional addition to Sprite/Midget – $725 price only applies to a cylinder head purchased with a rebuilt motor.

Additional Options:

New Pressure Plate – should be purchased if balance option is chosen, so it can be balanced with all other rotating parts $69.00

Camshaft – Scatter Pattern SPVP3 or SPVP4, your choice, (others available) $90.00

Convert to 11 studs – Requires Aluminum Cylinder Head and ARP studs $75.00

Tubular Chrom Moly Pushrods $69.00

Convert to use unleaded fuel — bronze valve guides & Stellite valve seats & valves $140.00

ARP Fasteners

Very high quality fasteners as used on most Spridget Race Motors:

Head Stud Set, includes rocker studs $125.00

Main Stud Kit $70.00

Flywheel Bolt Set $18.00

Rod Bolt and Nut Set $106.00

SHIPPING:

Shipped in custom crate which must be promptly returned.

Crate Core Charge is $125.00 (will be applied to orders when billed and refunded when the crate is returned) $125.00

Crating Charge $35.00

Shipping (actual cost) $120.00 to $450.00

If engine is purchased along with a five-speed overdrive conversion kit, the engine will be assembled with the aluminum adapter plate rather than the stock iron rear plate.