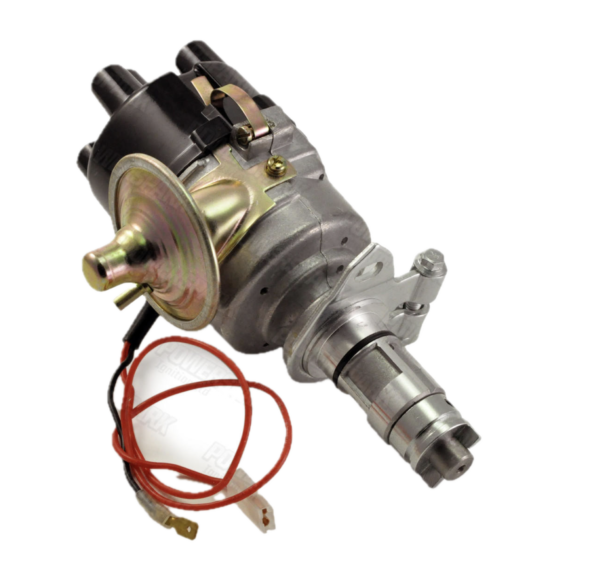

We previously used a Crane Fireball electronic ignition module in conjunction with the original Lucas 25D. We had the distributor rebuilt and recurved based on our engine modifications by Jeff Schlemmer at Advanced Distributor, However, after some research and discussion with A. C. Dodd, a U.K. “A series” engine tuner we decided to make a wholesale conversion to modern technology and purchased a Powerspark Lucas 45D Distributor. The Lucas 45D distributor replaced the 25D in 1975.

Powerspark manufactures the new distributor casting from an original Lucas model, so it visually appears like the original. The distributor is available in a number of variations. We selected a negative ground high energy model with Powerspark’s electronic ignition module with vacuum advance and top entry cap referred to as D5.

The distributor is a variable dwell design and the electronic module is capable of three times the spark of their standard sport module. This unit uses a non-ballasted .8 ohms coil and is not suitable for use with copper leads so we have used Cobalt carbon leads sourced from Moss Motors.

This YouTube video by A.C. Dodd does a nice job of explaining the desirability of transitioning to a modern electronic ignition distributor:https://youtu.be/nHOQzi-Je1I?si=NehsJxJQ6vHdZg1Z

At the same time that A. C. Dodd was modifying our new HIF 44 carburetor, we had him recurve our Powerspark dizzy to suit the modifications made to our engine. The unit is now set to reach maximum advance at 3,800 rpm.

We also decided to go with the Viper dry resin high energy .8 ohm coil sold by Powerspark.